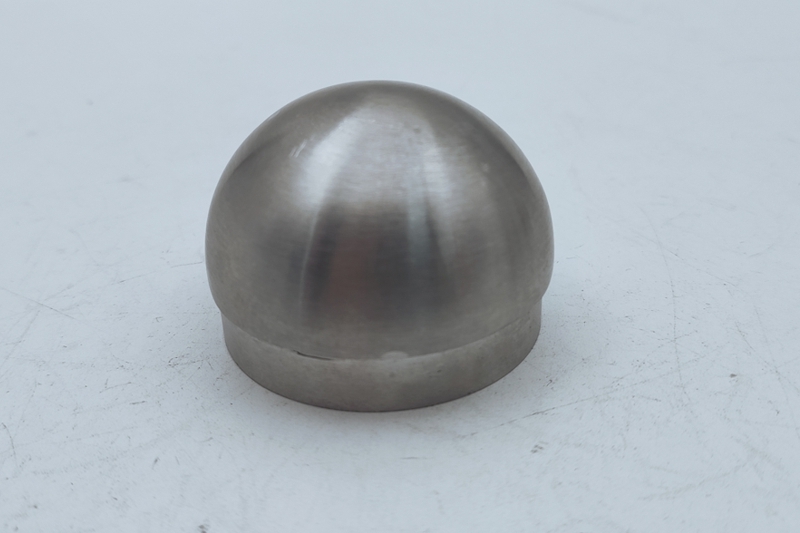

Stainless Steel Banister Brackets

- Product Information

Stainless steel banister brackets are key hardware components used to secure the connection between stair railings and walls or posts, providing users with stable support and a reliable sense of security. Their overall performance is characterized by stability, connection precision, and structural consistency under long-term use, making them suitable for building environments with specific requirements for public safety and durability.

Stainless Steel Banister Brackets Parameters:

| Model | GVF024 |

| Material | SS201 / SS304 / SS316 |

| Railing Diameter | φ38.1 / φ42.4 / φ50.8mm / Customized |

| Finish | Satin, Mirror Polished, Antique Brass, Antique Copper, Matt Black, PVD / Customized |

| After-Sale Service | Online Technical Support |

| Application | Shopping Mall, School, Hospital, Gym, Fitness Club, Office Building, Swimming Pool and Other Public Area |

| MOQ | 300 pieces |

| Place Of Origin | Guangdong, China |

| Brand Name | Glowing Hardware |

| Package | One piece in one white box/color box in Standard export carton |

| Delivery Time | Usually 30-35 days |

| Sample | Accept |

Stainless Steel Banister Brackets Features:

1. Material Consistency

Manufactured from SS201, SS304, or SS316 stainless steel, the material density is consistently maintained at approximately 7.85 g/cm³, with a clearly defined and controllable yield strength range. Through unified control of raw materials from the same batch, we ensure that each batch of Stainless Steel Banister Brackets maintains high consistency in terms of load-bearing performance and structural stability, reducing the risk of quality fluctuations at the construction site.

2. Precision Machining

The main body of the product is formed using CNC machining, with the flatness error of key connecting surfaces controlled within ±0.05mm, ensuring precise positioning of screw holes and support angles. This machining method effectively improves the fit of the Stainless Steel Banister Brackets after installation, preventing long-term loosening problems caused by uneven stress on the handrail.

3. Load-Bearing Structure

The internal structure is designed to match handrail diameters of φ38.1mm, φ42.4mm, and φ50.8mm, and each bracket can withstand a vertical static load test of ≥120kg. This load-bearing standard meets the safety design requirements for Stainless Steel Banister Brackets in most public buildings and is suitable for high-traffic areas.

4. Surface Treatment

Various surface treatments are available, including brushed, mirror polished, matte black, and PVD, with salt spray testing exceeding 24–72 hours. Through multi-layer surface treatment processes, the probability of oxidation and corrosion is effectively reduced, ensuring that the Stainless Steel Banister Brackets maintain stable appearance and performance in humid or high-traffic environments.

5. Customization Support

We support OEM customization of handrail diameter, base size, mounting hole positions, and appearance styles, with a design response time of 3–5 business days. Leveraging our mature engineering experience, we provide Stainless Steel Banister Bracket solutions that perfectly match the drawings for hotel and construction projects.

Stainless Steel Banister Brackets Application:

1. Commercial Buildings

In shopping malls and office buildings, Stainless Steel Banister Brackets are primarily used in stair and ramp handrail systems, meeting the stringent requirements for stability and safety in high-traffic areas. Standardized specifications help improve overall construction efficiency and reduce the frequency of future maintenance.

2. Healthcare Facilities

Hospital environments demand high standards for structural safety and ease of cleaning. The stainless steel material of Stainless Steel Banister Brackets facilitates daily disinfection and maintenance. Their stable support provides reliable assistance for patients and medical staff in stair areas, reducing the risk of accidents.

3. Educational Institutions

School buildings and public corridors require handrail systems for long-term use. Stainless Steel Banister Brackets can accommodate handrails of different diameters. Uniform installation standards effectively ensure the safety of people of all ages during stair use.

4. Office Spaces

In office building staircases and public corridors, Stainless Steel Banister Brackets facilitate the standardized installation of handrail structures. Their simple appearance and stable connection method ensure overall consistency in functionality and orderliness within the space.

5. Public Facilities

In places such as gymnasiums, swimming pools, and fitness centers, where humidity is high, Stainless Steel Banister Brackets, with their corrosion-resistant material and stable fixing method, ensure that the handrail system maintains reliable support even under frequent use.

Stainless Steel Banister Brackets FAQs:

Q: Do the Stainless Steel Banister Brackets support different handrail diameters?

A: They support common specifications such as φ38.1mm, φ42.4mm, and φ50.8mm, and can be customized according to project drawings to ensure a precise match with the on-site handrail dimensions.

Q: What is the product's lifespan in humid environments?

A: Made of stainless steel and treated with brushed or PVD surface finishes, the product can be used for a long time under normal maintenance conditions, making it suitable for swimming pools and public sanitary environments.

Q: Can you provide installation support for engineering projects?

A: We can provide installation guidance documents and technical support to assist engineering teams in correctly installing the Stainless Steel Banister Brackets, reducing on-site rework.

Q: Do you accept OEM or custom engineering orders?

A: We support OEM customization, including adjustments to structure, size, and surface finish, suitable for bulk purchasing needs of hotels and construction projects.

Q: What is the typical product delivery time?

A: The delivery time for standard specifications is approximately 30–35 days. Custom orders are confirmed based on complexity. The overall production cycle is stable and controllable, facilitating project scheduling management.