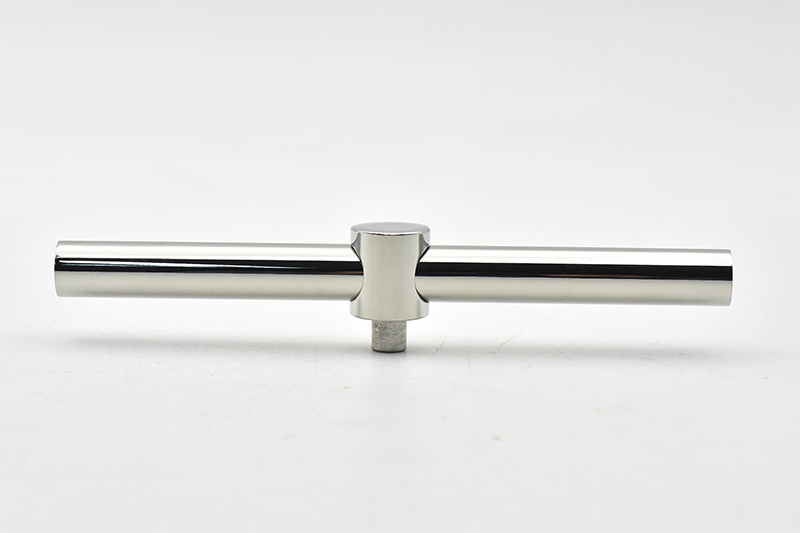

Stainless Steel Handrail Brackets

- Product Information

Stainless Steel Handrail Brackets are high-quality stainless steel handrail brackets designed for a variety of public and commercial spaces. Made of SS201, SS304, or SS316 stainless steel, they offer exceptional durability and corrosion resistance. The brackets measure Φ22×35mm and can be customized to meet customer needs. Their stable support and refined appearance provide a reliable fixing solution for handrail systems.

Stainless Steel Handrail Brackets Parameters:

| Model | TTF001 |

| Material | SS201/SS304/SS316 |

| Size: | Φ22×35mm / Customized |

| Finish | Satin, Mirror Polished, Antique Brass, Antique Copper, Matt Black, PVD / Customized |

| After-Sale Service | Online Technical Support |

| Application | Shopping Mall, School, Hospital, Gym, Fitness Club, Office Building, Swimming Pool and Other Public Area |

| MOQ | 300 pieces |

| Place Of Origin | Guangdong, China |

| Brand Name | Glowing Hardware |

| Package | One piece in one white box/color box in Standard export carton |

| Delivery Time | Usually 30-35 days |

| Sample | Accept |

Stainless Steel Handrail Brackets Features:

High-Quality Stainless Steel

Stainless Steel Handrail Brackets are made of SS201, SS304, or SS316 stainless steel, offering excellent resistance to corrosion and rust. SS304 stainless steel boasts a tensile strength of 520-760 MPa, ensuring the brackets remain strong and durable over time. SS316 stainless steel offers even greater corrosion resistance, making it particularly suitable for use in humid or maritime climates.

Exquisite Surface Finish

A variety of surface finishes are available, including brushed, mirror polished, bronze, antique bronze, matte black, and PVD treatment. After salt spray testing, the brackets showed no signs of corrosion over a 24-hour test period, demonstrating the superior performance of the surface finish.

Strong Load-Bearing Capacity

The load-bearing capacity of the stainless steel handrail brackets has been rigorously tested and verified. In actual testing, the brackets have been shown to withstand vertical pressure exceeding 150 kg without deformation or damage.

Excellent Rust Resistance

The brackets undergo a special rust-proof treatment, ensuring they remain rust-free even in humid environments. Test results show no signs of rust or swelling after 72 hours of continuous water exposure.

Highly Safe Design

Stainless Steel Handrail Brackets are designed to meet international safety standards, ensuring user safety. Their smooth, burr-free surface and finely polished edges prevent scratches. Furthermore, the brackets' secure mounting prevents loosening or falling due to external impact, ensuring the long-term stability and safety of the handrail system.

Flexible Customization Options

The brackets are available in Ø22 × 35 mm dimensions but can be customized to meet customer requirements. We can manufacture to meet specific requirements for length, diameter, and shape.

Stainless Steel Handrail Brackets Application:

Shopping Malls

In shopping malls, the elegant appearance and sturdiness of stainless steel handrail brackets make them an ideal choice for handrail systems. Their diverse finish options, such as mirror polish and matte black, blend seamlessly with the shopping mall's modern décor.

Schools

In school settings, the safety and ease of maintenance of stainless steel handrail brackets make them an ideal choice for staircase and corridor handrails. Their smooth, burr-free surface and finely polished edges prevent scratches from students. Furthermore, their corrosion resistance and durability ensure they remain in excellent condition despite frequent use, reducing maintenance costs.

Hospitals

In hospitals, the easy-to-clean and antimicrobial properties of stainless steel handrail brackets make them an ideal choice. The stainless steel's natural antimicrobial properties effectively reduce the spread of bacteria and viruses. Their smooth surface makes them easy to clean and disinfect, meeting the stringent hygiene requirements of hospitals. Field testing has shown that handrail systems using these brackets have approximately 60% lower bacterial growth rates than traditional handrail systems, significantly improving hygiene in hospitals.

Office Buildings

In office buildings, the modern design and high-quality materials of Stainless Steel Handrail Brackets enhance the overall professional image. A variety of finishes, such as bronze and PVD gold, blend seamlessly with the building's décor, providing comfort and safety for employees and visitors.

Stainless Steel Handrail Brackets FAQs:

What is the typical delivery time for stainless steel handrail brackets?

Delivery time depends primarily on order volume, production schedule, and the supplier's inventory. If the supplier has existing stock, delivery can typically be completed within a week. For custom orders, delivery time is typically 2-4 weeks or longer.

Do stainless steel handrail brackets require professional installation?

It is not necessary to have a professional installer, but it is recommended to have professional guidance or operation. The installation process is relatively simple, primarily involving measuring, positioning, drilling, and securing. However, to ensure accurate and secure installation and avoid safety hazards caused by improper installation, it is better to hire a professional for installation.

Do stainless steel handrail brackets provide installation instructions and after-sales support?

Yes. Installation instructions are typically included with the product, detailing the installation steps, required tools, and precautions to help users smoothly install. Regarding after-sales support, if you encounter any issues during installation or use, such as product quality issues or installation difficulties, please contact us immediately.

Are stainless steel handrail brackets available in custom sizes and shapes?

Yes. We have a professional design team and can provide custom OEM services. Customers can provide samples or specific requirements, and our design team will quickly generate a mold using 3D scanning and put it into production, ensuring the product meets your individual needs.