At Glowing Hardware, we specialize in delivering superior hardware solutions tailored for high-end hotels, construction projects, architectural applications and others. With a focus on innovation, quality, and technical expertise, we serve trade companies, manufacturers, and global design firms with custom OEM services, installation support, and problem-solving excellence.

Case Study: Resolving Concealed Hinge Failures in Abu Dhabi’s Premier Apartment Project

In 2022, a trusted client in the UAE faced a critical challenge during the final inspection of their luxury apartment development in Abu Dhabi. The project featured three 10-story buildings with a range of doors, including entry doors, internal doors, privacy doors, and safety-compliant DDA doors. While the client had sourced door handles, Mortise Locks, magnetic stops, and closers from Glowing Hardware, they had procured concealed hinges from another supplier due to time constraints.

The Problem: Systemic Hinge Failures

In early July 2022, during inspection, their inspection team discovered a broken concealed hinge on an internal door. The customer believed this was an isolated incident and that all hinges on that door would be replaced. Therefore, the customer removed all the hinges and installed new ones. On July 19, 2022, the inspection team discovered another broken concealed hinge. At this point, they decided to inspect all concealed hinges and ultimately discovered many defective products.

Since the customer and Glowing Hardware have been cooperating since 2016, and the sales representative and the customer's technical staff have always had a close relationship, the customer asked the Glowing Hardware team to help analyze the cause and sent samples of defective products to Glowing Hardware.

Our Approach: Advanced Manufacturing & Precision Engineering

1. Diagnostics & Analysis

After receiving the sample, Glowing Hardware's technical team immediately held a meeting to help the customer analyze the cause and finally came to a conclusion:

Material Deficiency: Substandard casting processes resulted in low-density connections prone to stress fractures.

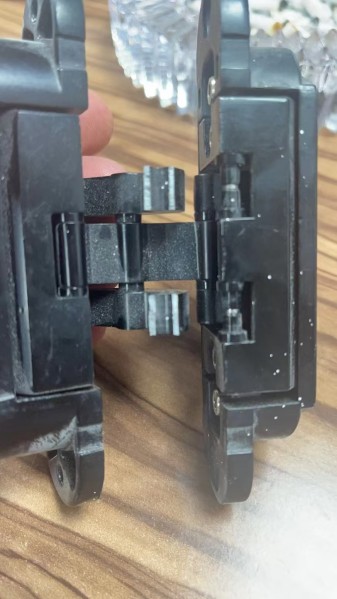

Design Flaws: Limited 3D adjustability caused misalignment, leading to shell deformation under load.

2. Material Innovation: Stainless Steel Precision Casting

Glowing Hardware's technical team developed a proprietary stainless steel precision casting mold to produce hinges with exceptional structural integrity.

Process: Molten steel (1000°C+) was cast using investment (lost-wax) methods, ensuring high dimensional accuracy and uniform density.

The advantages of stainless steel investment casting are: It uses a dewaxing process to cast molten steel at temperatures above 1000 degrees Celsius, followed by air drying and forming. The resulting castings have higher dimensional accuracy and surface quality than other casting methods. Stainless steel investment casting is suitable for complex, high-temperature-resistant, and difficult-to-machine castings.

Result: Hinge joints achieved superior load-bearing capacity and resistance to deformation.

3. Enhanced Functionality: 3D Adjustability

We've designed an enhanced shell mold to allow for seamless three-way adjustability (vertical, horizontal, and depth).

Installers could fine-tune hinges with standard tools, eliminating stress from door-frame misalignment.

4. Validation & Testing

Before mass production, we completed a prototype for the customer's approval. Meanwhile, Glowing Hardware's technical team conducted functional testing on the concealed hinge. We simulated the opening and closing of the door, subjecting the concealed hinge to 100,000 cycles of opening and closing. The test lasted about 10 days, with the machine running non-stop until the 100,000 cycles were completed.

5. Finishing Excellence

Since the client's project is a high-end one, Glowing Hardware's production team is well aware of the importance of product appearance. Therefore, during the polishing and coating process, the workers completed these processes very carefully, and the QC team also carried out inspections according to strict standards.

Polishing & Coating: Mirror-finish polishing and anti-corrosion coatings applied for aesthetics and durability.

QC Rigor: Each hinge underwent stringent inspections for dimensional tolerance, finish quality, and mechanical performance.

The Outcome: A Trusted Partnership Strengthened

Glowing Hardware completed product design, mold development, sample testing, and mass production within 70 days. We delivered a full batch of hinges that met the project’s premium standards, ensuring on-time completion. Our client praised the solution’s reliability and our ability to transform a crisis into an opportunity for innovation.

Why Choose Glowing Hardware?

Proprietary Manufacturing: Cutting-edge processes like precision casting for unmatched product longevity.

End-to-End Expertise: From design to installation, we solve problems others can’t.

Global Standards: Solutions tailored for demanding projects worldwide.

If you have any questions about hardware, please feel free to consult us and we will try our best to provide you with professional help.