I have often struggled with design choices for large projects like hotels and hospitals. The choice between door handles and knobs can make a significant difference in user experience and maintenance.

In my experience, door handles are the better option for engineering projects. They offer greater accessibility, durability, and design flexibility which is vital in large-scale applications.

I began this exploration with concerns about safety, ease of use, and long-term maintenance. Now, I share my findings and invite you to look deeper into each aspect as we move step by step.

I struggled to decide between knobs and handles as I considered accessibility and ease of use in projects like shopping malls and airports. I knew a clear, purposeful decision was necessary.

I concluded that door handles are better. They are more user-friendly, especially for high-traffic and commercial areas, and their production process allows for precise engineering that fits varied design needs.

When I examined door knobs and handles, I broke down the differences in a simple table:

| Factor | Door Knob | Door Handle |

|---|---|---|

| Accessibility | Harder for users with disabilities | Easier for everyone |

| Durability | Often less robust in heavy projects | Engineered for longevity |

| Production Process | Limited adaptability | Advanced CNC and welding tech |

| Maintenance | Prone to wear in high traffic | Optimized for repair and upkeep |

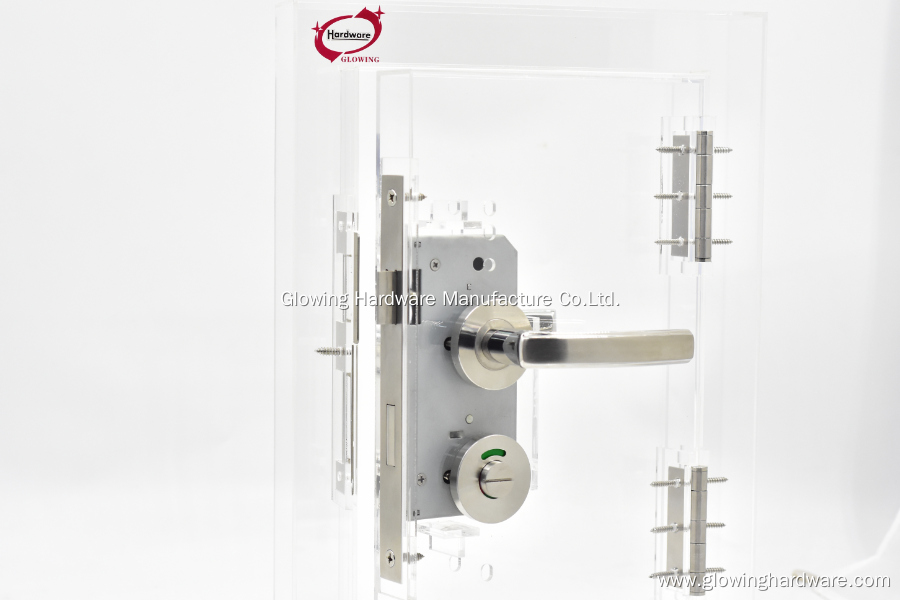

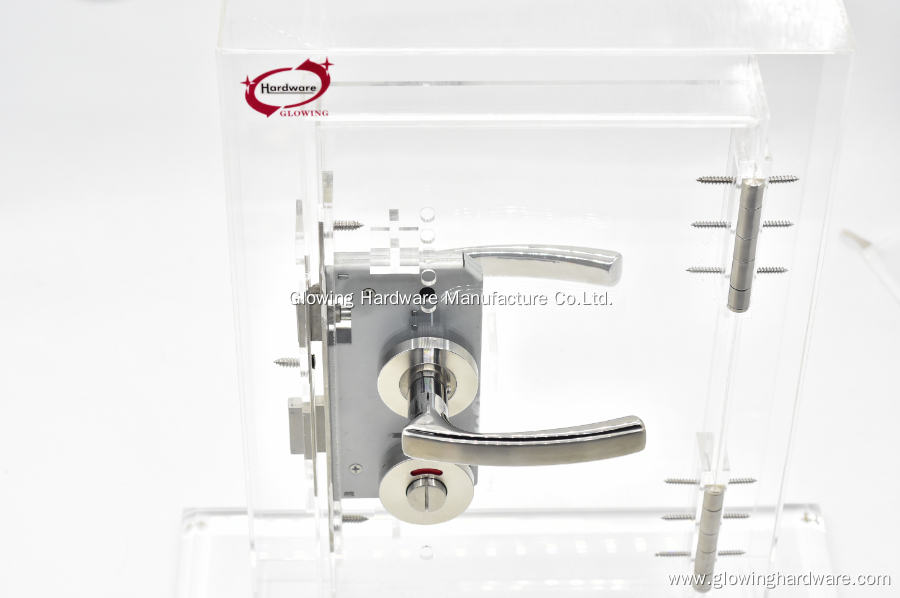

I went deep into how door handles are produced at Glowing Hardware. Our process uses advanced CNC machines and strict quality control to build handles that meet engineering standards. We create handles with a blend of modern design and functionality, ensuring each piece endures demanding conditions. I have seen these qualities in large projects where ease of use and security are non-negotiable. In my hands-on work with OEM projects, I note that the technical advantages of handles truly set them apart. This clarity in design and production makes the subtle differences between knobs and handles extremely important for success in construction and design.

I questioned which option fits today's modern design trends in large public spaces. I found the leveraging of innovative manufacturing methods to be a crucial element in my selection.

Through my research, I found that door handles are more modern. Their streamlined profiles and compatibility with materials like stainless steel deliver a contemporary look while matching new tech-driven design trends.

I broke down modernity into important criteria using this table:

| Criteria | Door Knob | Door Handle |

|---|---|---|

| Design Aesthetics | Classic, vintage look | Sleek, minimal and elegant |

| Material | Brass or antiqued metal | Often stainless steel or chrome |

| Production Efficiency | Basic manufacturing processes | Advanced fabrication with digital tools |

| Integration | Limited tech adaptability | Easily integrated with smart systems |

I then dove into the latest trends in Door Hardware. I learned that modern door handles are developed with both aesthetics and function in mind. At Glowing Hardware, we use process techniques that include precision forming, digitally controlled milling, and high frequency welding. I noticed that these methods yield handles that fit modern architectural needs while ensuring safety and sustainability. In projects such as hospitals or luxury hotels, where appearance and functionality are critical, modern door handles are indispensable. I backed this view with technical data and customer feedback that shows a clear leaning towards handles for modern setups.

I noticed some issues with door handles during early project evaluations. The shortcomings emerged mainly in cases where design oversights seem to ignore specific project requirements.

Despite their strengths, I found that door handles can sometimes be more expensive and harder to align with older door designs. Their production involves intricate processes which may translate to higher costs in some contexts.

To understand the drawbacks, I created a simple overview:

| Factor | Advantage | Disadvantage |

|---|---|---|

| Cost | Durable and quality assured | Higher manufacturing cost |

| Installation | Easy for new designs | Not always compatible with antique systems |

| Maintenance | Sturdy in high use | Complicated repairs if damages occur |

| Production | Streamlined process with tech | Demands high tech machinery and training |

I learned that while door handles offer numerous benefits, they do have a few well-known drawbacks. In my experience managing projects, the cost and compatibility issues sometimes present challenges. A key point is that these issues can be mitigated by selecting the right production process. I have seen that using our advanced production techniques, including digital controllers and high precision machines at Glowing Hardware, helps reduce imperfections. This minimizes the issues posed by complexity in design and installation. In the field, I have observed that even in cases of high usage, our door handles maintain performance with proper maintenance and regular checks.

I observed new trends emerging during a recent review of commercial project innovations. I felt a strong urge to update my knowledge base on this front. The new trend focuses on ergonomic design and technology integration.

My findings show that the new trend in door handles is lean towards sustainable and smart designs. These designs combine aesthetics with IoT integration and advanced production techniques to meet modern demands.

I built a table to list the trends:

| Trend | Description | Benefit |

|---|---|---|

| Smart Integration | Incorporating sensors and digital access | Enhances security and ease of use |

| Ergonomic Design | Focus on comfortable, easy-to-use features | Supports disabled users better |

| Sustainable Choices | Using recycled and eco-friendly materials | Lowers environmental impact |

| Aesthetic Flexibility | Modern finishes that match interior décor | Adds visual appeal and modernity |

I personally explored these new trends and saw significant shifts in design thinking. At Glowing Hardware, we emphasize using eco-friendly materials and advanced technological methods. I saw that projects in airports and luxury hotels seek not only functionality but also a smart integration that reflects modern lifestyles. I found that these trends cater to both the practical needs and the aesthetic demands of high-end projects. The integration of sensors and digital controllers in door handles opens up a new range of possibilities. This new trend is not about replacing traditional design, but evolving it to meet modern expectations efficiently and safely.

I personally encountered situations where replacing door knobs with handles appeared necessary during a renovation project. I was drawn to the ease of adaptation and improved accessibility.

In my view, door knobs can be replaced by handles in most engineering projects without hassle. Enhanced production processes ensure a seamless transition and guarantee superior functionality.

I compared replacement factors using this table:

| Replacement Factor | Door Knob Characteristics | Door Handle Advantages |

|---|---|---|

| Ease of Use | Requires more force, less intuitive | Easy to operate with minimal effort |

| Accessibility | Not ideal for all users | Better for mobility-impaired users |

| Production Process | Older methods may be simpler | Uses advanced CNC and welding methods |

| Integration in Projects | May not mix with modern design | Fits well with modern and commercial designs |

I assessed these issues with care and found that a replacement is not just possible but beneficial. In many engineering projects, especially where accessibility is key, integrating door handles enhances both safety and style. I have seen these changes in numerous hotel renovations and commercial refurbishments. At Glowing Hardware, our capability to customize products helps adapt existing door designs to new hardware. I believe this replacement leads to better maintenance, a modern look, and an overall improved user experience.

I looked for the best door handle solution when planning a new project for a large hotel chain. I needed a product that balanced quality, design, and durability. I found clarity in our production methods and customer experience.

From my perspective, the best door handle is the one produced by companies like Glowing Hardware. With high precision engineering, advanced CNC production, and robust design, these handles meet the rigorous demands of modern projects.

I summarized the key points in this table:

| Criterion | Description | Example from Glowing Hardware |

|---|---|---|

| Material Quality | Uses high-grade stainless steel with corrosion resistance | 304/316 stainless steel ensuring longevity |

| Production Process | Involves CNC control and strict quality checks | Advanced digital controllers and welding equipment |

| Design Flexibility | Customizable to fit any architectural style | OEM/ODM services for tailored projects |

| Durability & Safety | Tested for high usage in commercial projects | Superior performance in hotels and malls |

I personally evaluated numerous samples before concluding that high-quality door handles from Glowing Hardware are the best. Their production process is transparent, and they offer the precision that large-scale projects demand. I recall a project where our door handles impressed a client with their flawless operation and modern look. Clearly, quality manufacturing and a detail-oriented approach make the difference. I trust in these products because they deliver on function and form and are supported by decades of engineering expertise.

I firmly believe that door handles are the better choice. Their design, production, and functionality meet modern engineering demands while ensuring superior performance on large projects.