I faced many issues with heavy doors in my hotel projects until I found a

clear method with solid data and reliable production processes . I learned

that using extra hinges ensures strength and safety.

For heavy hotel doors, I strongly recommend using at least three heavy-duty hinges, built with thick stainless steel to support the weight and frequent

usage. This approach guarantees durability and alignment with quality

standards .

I started with many doubts on where to begin with door installations. Now I have clear steps and proven methods that guide me through every installation. I promise clear guidelines.

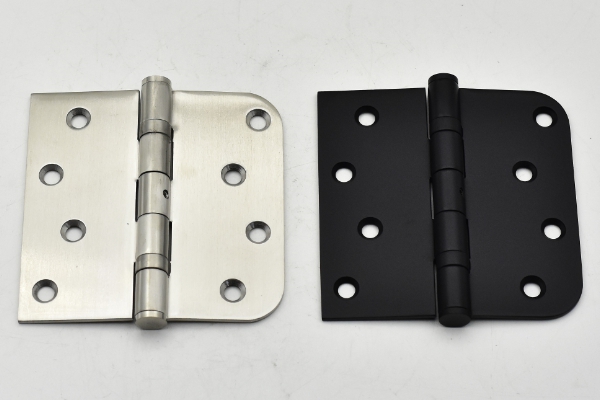

I struggled with selecting the right hardware for my heavy doors until I found

reliable heavy-duty stainless steel hinges that support weight and resist

corrosion . They provided the strength needed for hotel use.

Heavy-duty stainless steel hinges are a must. I use hinges with dimensions of

3.5 to 6 inches for commercial doors. They are made with advanced technology

and strict quality control .

I researched various hinge types and leaned on my years in the industry to decide. I compared stainless steel hinges with other materials and saw that heavy-duty stainless steel provided the best performance under heavy usage. In my experience, a good hinge for heavy doors must distribute the load evenly and bear frequent use without warping. I then evaluated hinges based on size, material quality, and production process. Below is a summary table of hinge types and their recommended usage:

| Hinge Type | Recommended Width | Door Weight Capacity | Recommended For |

|---|---|---|---|

| Standard Commercial | 2.5 to 3.5 inches | Up to 60 lbs | Residential and light commercial |

| Heavy-Duty Commercial | 3.5 to 6 inches | 60 to 100+ lbs | Hotels and large access doors |

| Extra Heavy-Duty | 4+ inches | Over 100 lbs | High-security hotel doors |

I use products from Glowing Hardware because of their precise manufacturing methods that include CNC machining and high-frequency welding. These processes guarantee the hinge quality and its suitability for high-traffic areas such as hotel door installations. I have seen firsthand how rigorous production processes lead to long-lasting performance. I promise clear guidelines.

I needed assurance that every component of my heavy doors worked in harmony. I

realized that the right hinges not only support the door but also improve

safety and ease of use .

Hinges are key to a door's structural integrity. They enable the door to

operate smoothly and securely while withstanding frequent use. For hotel

projects, reliable hinges are essential to avoid misalignment or premature

wear .

I later studied how hinges affect door performance and safety. My investigation showed that the right hinge design reduces stress on the door, preventing sagging or warping over time. I found that a poorly chosen hinge can lead to discomfort for users and higher maintenance costs. In hotel projects, where doors see continuous use, quality hinges are a critical factor in maintaining the door's function, safety, and appearance. To quantify their importance, I consider the following points:

| Factor | Impact on Door Performance | Maintenance Frequency |

|---|---|---|

| Load Distribution | Even distribution avoids warps | Lower maintenance |

| Material Quality | High resistance to wear and corrosion | Extended lifespan |

| Installation Accuracy | Precise installation reduces misalignment | Fewer repairs |

This studied approach has helped me design projects that meet both functionality and aesthetics. It is clear that investing in the right hinges saves time and money. I promise clear guidelines.

I was unsure how to match the door's weight with the right number of hinges

until I used a simple calculation method . I measured the door’s weight and

dimensions and applied practical industry guidelines.

I calculate the hinge count by first weighing the door and considering its

usage frequency. For heavy hotel doors, I add an extra hinge for safety. I

usually use three or more hinges for a door over 100 lbs to distribute stress

evenly .

I learned that calculation involves both practical tests and standard principles. My process starts with measuring the door's dimensions and estimating the weight, either by direct weighing or by evaluating the door’s material and build quality. I then refer to standard guidelines which categorize doors by weight: doors up to 60 lbs work with two hinges, while doors over 100 lbs require three or more. I also consider door usage; for frequently operated hotel doors, extra hinges provide redundancy and safety. I break these insights into a simple table:

| Door Weight | Standard Hinge Count | Additional Consideration |

|---|---|---|

| Up to 60 lbs | 2 hinges | Light usage recommended |

| 60-100 lbs | 2-3 hinges | Moderate use |

| Over 100 lbs | 3+ hinges | Heavy usage, extra for safety |

This method, coupled with Glowing Hardware’s advanced quality control, has let me reliably determine the number of hinges per door. The precision in measurement ensures durability and customer safety. I promise clear guidelines.

I noticed that size really matters when handling heavy doors in hotel

settings. I found that using larger hinges helps by evenly sharing the weight,

leading to better function and longer lifespan .

I choose hinges that are at least 4 inches wide for heavy doors. This size

supports the door’s weight and meets the high usage demands of hotel projects

while ensuring quality and durability .

I dug into the specifications and discovered that the hinge’s size affects its load-bearing capacity and longevity. In my experience, even a slight increase in hinge size can significantly reduce wear and tear on the door and the frame. I typically work with sizes from 3.5 to 6 inches for medium to heavy doors. It is essential to match the hinge size with the door’s thickness and weight. Lower quality hinges may fail quickly, leading to costly repairs. I charted out the hinge sizes along with their corresponding door weights to help me pick the correct hardware:

| Door Thickness & Weight | Recommended Hinge Size | Suitable For |

|---|---|---|

| Light but thin doors | 2-3 inches | Residential light usage |

| Medium doors | 3-4 inches | Standard commercial projects |

| Heavy and thick doors | 4+ inches | Hotels, commercial buildings |

This structured method of choosing ensures the hinges have the proper strength and are manufactured to high standards using advanced technology. Glowing Hardware provides me with parts that are made via CNC controls and rigorous quality checks which I trust for all my projects. I promise clear guidelines.

I learned that the placement of hinges is as important as the quality and size

of the hinges themselves. I found out that proper location helps distribute

the door's weight and ensures smooth operation in busy hotel lobbies .

I generally place one hinge at the top, one at the bottom, and one in the

middle of the door. This layout ensures balanced support for heavy doors,

meeting hotel safety guidelines while optimizing usage .

I started experimenting with different placements in my early projects and soon noted that a misaligned hinge causes irregular swinging and possible damage to the door frame. I now use a three-point installation layout which evenly splits the weight along the door's height. A proper layout not only prevents warping but also reduces stress on individual hinges. In my experience, an evenly spaced layout leads to improved door longevity and enhanced security. I often refer to a simple guide that aligns with standard practices:

| Hinge Position | Function | Benefits |

|---|---|---|

| Top Hinge | Supports the door’s upper weight | Prevents sagging at the top |

| Middle Hinge | Balances overall weight | Maintains smooth operation |

| Bottom Hinge | Secures the door at the base | Ensures stability |

This method, backed by precise manufacturing and testing at Glowing Hardware, ensures safety and durability of the door installations in hotel projects. I promise clear guidelines.

I once wondered if the hinges should be positioned on the inside or outside of

a door, especially in high-traffic hotel settings. I found that for security

and aesthetics, the best option is to install them on the interior side .

For hotel doors, I always place hinges on the interior side. This protects

them from weather elements and potential vandalism, while maintaining a clean

exterior look .

I explored different installation methods and learned that interior placement offers a more controlled environment for hinges. In my work with hotel doors, I discovered that placing them inside prevents unnecessary exposure to harsh weather and reduces the risk of damage from external forces. I also learned that inside installation supports better alignment and maintenance. A controlled interior environment allows for easier repairs and ensures longevity of the Door Hardware. Manufacturers like Glowing Hardware design their products to work optimally when installed on the interior, ensuring that the hinge's moving parts stay lubricated and less affected by external corrosive factors. I base my installations on this guiding principle, as it has consistently resulted in high-performing doors in my projects. I promise clear guidelines.

I used to make mistakes when installing door hinges until I adopted a

step-by-step process that made every installation smooth and reliable . I now

follow strict guidelines and quality checks to always get it right.

The correct way to install door hinges is to pre-mark the alignment points on

both the door and frame, pre-drill the screw holes, and finally, secure the

hinges tightly. This ensures durability and optimal function .

I rebuilt my installation process after learning from failed attempts in early projects. I now begin by measuring and marking the door to ensure the hinge positions are exactly aligned with the door frame. I then pre-drill small pilot holes to avoid wood splitting and to ensure the screws go in easily. During this process, I always check that the hinge leaves meet perfectly and that the door swings smoothly. A proper installation also requires a final check with a level tool, ensuring the door hangs evenly. I use high-quality tools and fasteners sourced from Glowing Hardware, which are manufactured under strict quality control standards. Their production process, which includes CNC technology and rigorous testing, gives me the confidence that each installation will be secure and safe for hotel projects . I promise clear guidelines.

I now confidently install heavy hotel doors with at least three heavy-duty hinges using proven methods. I promise clear guidelines.