My client with another supplier encountered a major issue where a door handle in a department project did not remain vertical, leading to aesthetic and safety concerns.

The problem was ultimately traced to significant deformation of the spindle under high torque loads, which caused the door handle to sag and not align properly.

My clinent ask for the solution from us. I felt it was crucial to understand the root cause and share a detailed investigation that led to an effective solution.

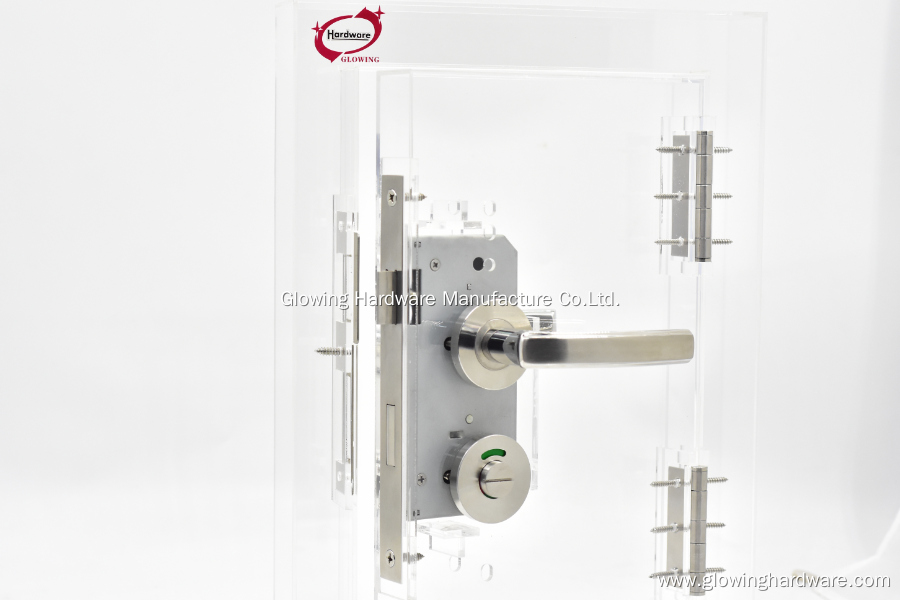

I learned that the spindle is the core component in a door handle assembly that allows for rotation and alignment, making its design and material properties vital to proper function.

The spindle, serving as the connecting rod between the door handle and the internal locking mechanism, must be robust enough to resist high torque forces without deforming.

My investigation revealed that the standard spindle dimension is 8.0x8.0mm, yet in this particular case, an unconventional dimension of 8.3x8.3mm was used, increasing stress on the component. I organized my observations as follows:

| Parameter | Standard Specification | Actual Specification | Impact on Performance |

|---|---|---|---|

| Spindle Dimensions | 8.0 x 8.0 mm | 8.3 x 8.3 mm | Higher stress concentration leads to greater deformation |

| Material Quality | Typically high strength steel | Lower-grade material | Inadequate resistance to high torque forces |

| Torque Resistance | Sufficient for standard use | Insufficient for heavy duty | Increased risk of deformation under high load conditions |

This analysis indicated that using a spindle unable to withstand high torque resulted in its deformation, causing the door handle to fail in remaining vertical.

The project, located in Singapore, involved 10 buildings with 20 floors each, and featured heavy-duty fire and security doors.

During routine inspections, the client’s team discovered that the door handles—supplied by another vendor—were not staying vertical. Detailed tests revealed that the spindles experienced obvious bending and deformation under load.

In October 2023, during an on-site inspection, technicians repeatedly operated the door handles and observed that they deviated from vertical alignment, although the doors functioned normally. Concerned about the potential safety hazards and the aesthetic impact, the client collaborated with us for a deeper investigation.

A supervisor mounted several door handle units on a testing machine and applied maximum force. Video recordings captured severe spindle bending and deformation, confirming that the handles could not meet the required resilience for heavy-duty usage.

Recognizing that the visual evidence was not enough to pinpoint the issue, the client sent actual samples to us for precise torsion testing. Our results showed that slight deformation began at 30N/m, but significant bending occurred at 50N/m, a load level common in heavy-duty fire doors.

This testing confirmed that the primary fault was the significant deformation of the spindle due to inadequate material strength and non-standard dimensions. The client's decision to seek improvement stemmed from the necessity to replace the failing door handles with a robust alternative that could endure higher torque and maintain vertical alignment.

I realized that to fix a door handle falling off, it is critical to address the root cause—spindle deformation—and ensure the connector’s integrity.

The solution involves upgrading the spindle material and refining its design to better distribute torque, preventing deformation and ensuring that the handle remains securely in position.

I broke the solution into clear steps:

First, replicate the problem under controlled conditions where the original door handle consistently showed spindle bending under high torque.

Next, upgrade the material by selecting a higher-grade steel, such as 45# carbon steel, known for its superior strength and resistance to deformation.

Adjust the spindle design to accommodate the correct dimensions and improved load distribution.

Conduct rigorous testing using torsion loads higher than the expected use (up to 90N/m) to verify that the new design maintains vertical alignment without deformation.

The table below summarizes the approach:

| Step | Action Taken | Outcome Achieved |

|---|---|---|

| Problem Replication | Tested original door handles under high torque | Confirmed spindle deformation was the cause |

| Material Upgrade | Adopted high-strength 45# carbon steel | Enhanced strength and resistance to bending |

| Dimensional Refinement | Modified spindle dimensions/design | Improved load distribution and stability |

| Rigorous Testing | Applied higher than normal torsion loads | Verified that door handles remained vertical |

This methodical approach ensures that the door handle will remain secure, addressing the core issue of spindle deformation.

I encountered another related problem where the door handle failed to return to its original position, which was traced back to the deformed spindle.

A door handle may not spring back up if its spindle has bent or lost its rigidity, meaning that the spring-back mechanism is compromised. Using a strong, well-designed spindle is essential to maintain the handle's proper function.

In detailed tests, it was evident that when the spindle deforms, the door handle loses its ability to return reliably to vertical after being pressed. The upgrade to robust 45# carbon steel reinforced the structure, allowing the handle to spring back effectively even under repeated stress. This improvement restored the handle’s functionality and ensured consistent performance.

I discovered that an unstable door handle or a spindle that tends to come apart is usually due to loose connections combined with a weak spindle design.

The corrective action involves securing the assembly by tightening machining tolerances and using robust materials, ensuring that the door handle and spindle remain firmly connected even under heavy use.

Upon closer inspection, it became clear that even minor vibrations or repeated use could cause the spindle to loosen from its fitting. By revising the assembly design—tightening the tolerances and reinforcing the joint—the spindle was better secured. This redesign, validated by subsequent high-torque tests, ensured that the door handle assembly would remain stable and secure during continued operation.

I believe that selecting the right door handle requires balancing functionality, material strength, and design aesthetics.

When choosing a door handle, consider the door’s specific usage, the torque it must bear, and the component’s overall construction. Opt for hardware that uses high-grade materials like 45# carbon steel and is manufactured to precise dimensions to ensure reliable performance under stress.

I recommend evaluating these key factors before making a selection:

Determine the door type (e.g., heavy-duty security or exterior door) and the environmental load it may face.

Ensure the handle’s spindle is made from a strong, resilient material.

Verify that the design allows for precise manufacturing, offering tight connections for enhanced stability.

Check that the product has undergone comprehensive torsion and load testing to confirm its durability.

The table below outlines the selection criteria:

| Selection Factor | Recommendation | Justification |

|---|---|---|

| Door Type | Heavy-duty or security door | Requires extra strength and durability |

| Material Quality | High-grade metals (e.g., 45# carbon steel) | Withstands high torque and repeated stress |

| Design Accuracy | Precisely machined components | Ensures secure connections and proper alignment |

| Testing Standards | Rigorous load and torsion testing | Confirms dependable performance even under high stress |

Following these guidelines can help ensure that the door handle you choose will not only function perfectly but also enhance the aesthetic appeal of your space.

The door handle’s failure to stay vertical was due to significant spindle deformation under high torque loads, and addressing this required upgrading the material and refining the design.