Upgrading a Door Lever Handle is a systematic engineering project. It blends industrial design, materials science, welding technology, verification testing and fast project execution. The following case shows exactly how Glowing Hardware upgraded a long-selling lever handle so it could move from timber doors to metal doors and pass European heavy-duty standards.

A Belgian distributor with more than fifteen years in local Door Hardware asked us in late August 2023 to upgrade its mainstream lever handle. The product had always served ordinary timber doors. The new goal was to make it suitable for metal doors and to refresh the visual quality of the tail end. At the same time the insert needed to meet European heavy-duty door testing with a minimum torsion resistance of 80 N·m.

Two explicit upgrade targets

Make the hemi-spherical tail look more premium.

Enable the insert to pass heavy-duty standards at not less than 80 N·m.

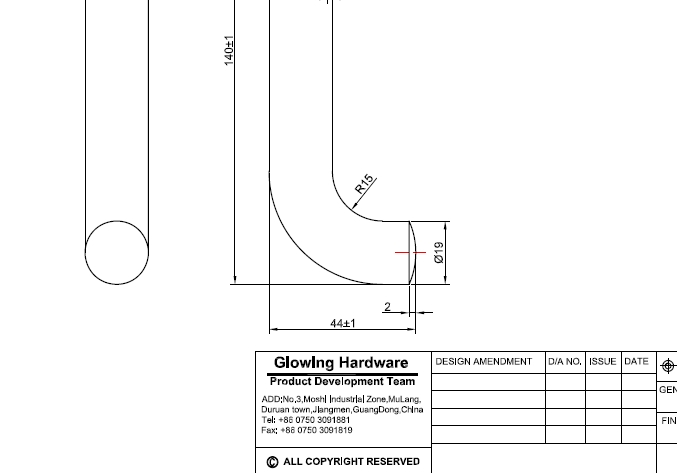

Once our sales team relayed the brief to engineering, we rebuilt the original handle as a parametric model in SolidWorks. The team adjusted the geometry of the hemi-spherical tail by fine-tuning the curvature radius and transitions, then issued revised 2D drawings for customer approval. The approach ensured the surface looked higher grade while staying compatible with existing assemblies.

Our in-house toolroom opened the mold immediately after drawing approval and finished it in 15 days. Trial shots and machining were completed to produce the first upgraded samples, which the customer reviewed and accepted for appearance and feel. This closed the industrial design phase and allowed us to move to strength engineering.

The legacy insert material was brass. To raise torsional resistance while keeping the material unchanged, engineering doubled the length of the brass insert and assembled it into the handle. We began verification with a base torsion test at 40 N·m. The result was negative. The handle deformed before reaching the target and the brass insert did not hold the load. This data showed that lengthening alone was insufficient.

Our sales team had previously researched German lever handles online and proposed a new route. Replace the brass insert with a stainless steel insert and join it to the tube by a full-welded process that fuses the parts into a single structure. This cross-functional suggestion was adopted and sent to production for prototype making.

We machined a stainless steel insert to match the original geometry and executed a full weld to the lever tube. Externally, the stainless version and the original brass version looked identical, which protected the customer’s market identity. After welding, the surface showed no discoloration and no thermal distortion. Dimensional checks confirmed conformance to drawing with small tolerances. The weld trace was invisible and the surface remained smooth and high end.

The upgraded handle easily cleared the 80 N·m requirement. Continuing the pursuit of margin, we raised the test load and confirmed that the handle with the stainless full-welded insert sustained 100 N·m with no deformation. This closed the mechanical validation with clear evidence of reliability for heavy-duty metal doors.

We documented the results, explained the welding principle and dimensional stability to the client and shipped samples by FedEx for their internal tests. From receipt of the initial request to delivery of tested samples, the cycle was twenty-eight days. The client confirmed performance and placed a purchase order.

SolidWorks digital redesign The upgraded hemi-spherical tail was modeled in SolidWorks to refine the radius and create a premium look while ensuring dimensional accuracy.

Mold and rapid prototyping New tooling was developed within 15 days, demonstrating efficient project execution and enabling fast customer feedback.

Failure-driven improvement Doubling the length of the brass insert showed in torsion testing that material strength, not just geometry, was the limiting factor. This guided the decision to switch materials.

Material innovation Stainless steel replaced brass to provide higher yield strength, greater torsion capacity and longer service life.

Full-welded joint technology The stainless insert was fully welded into the lever tube, eliminating slippage and spreading load across the structure. This guaranteed torsion resistance without visible weld marks.

Dimensional and surface quality control Welding parameters were strictly managed to prevent discoloration, deformation or tolerance drift. The surface remained smooth and consistent with a high-end finish.

Performance verification Testing confirmed compliance with the 80 N·m European requirement and showed reserve strength up to 100 N·m, ensuring safe use in heavy-duty metal doors.

Material selection Stainless steel’s mechanical advantage was critical in meeting torsion standards.

Full-welded structure Integration of insert and lever tube created a single rigid load path.

Design compatibility The external appearance was unchanged, protecting customer branding.

Serve hotel projects and architectural engineering clients with tailored door hardware solutions

Provide OEM customization with a professional design team

Offer installation guidance for smooth rollout

Solve technical problems quickly and transparently

Deliver full solutions from concept to verification to shipment

These service pillars are exactly how we executed the Belgian upgrade in record time.

By applying SolidWorks digital design, rapid mold development, stainless steel material substitution, and full-welded technology, we successfully upgraded a traditional timber-door lever handle into a high-end solution that meets and even exceeds European heavy-duty standards. From receiving the request to delivering tested samples, the entire process was completed within 28 days. Glowing Hardware as a trusted partner capable of delivering fast, reliable, and market-ready solutions. If you have any questions, you can consult us and we will serve you wholeheartedly.