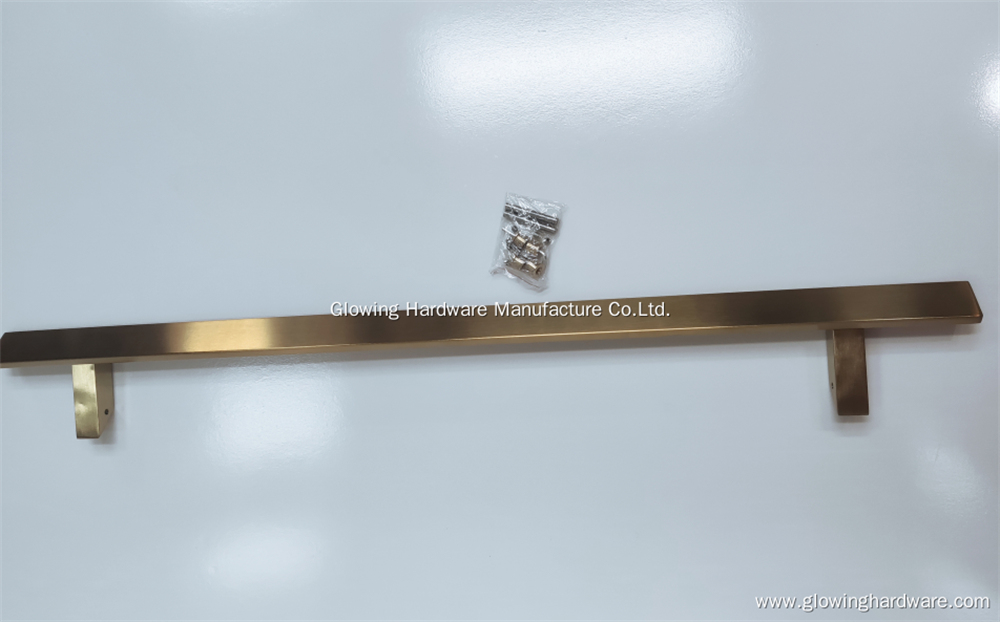

Stainless Steel Cabinet Door Pulls

- Product Information

Stainless Steel Cabinet Door Pulls is a cabinet door accessory made of high-quality stainless steel, designed for modern homes and architectural spaces. It is not just a simple tool for opening and closing cabinet doors, but also an important element to enhance the beauty and overall style of the cabinet. This handle has won the favor of a large number of users with its simple and smooth lines, modern design, and excellent user experience.

Stainless Steel Cabinet Door Pulls Parameter:

| Model Number: | HB022 |

| Product name: | Stainless steel door pull handle |

| Material: | SS304 / SS316 |

| Handle size: | Customized |

| Tube diameter: | Customized |

| Finish: | SSS/PSS/PVD/SN/CP/AB/AC/customized |

| After-sale Service: | Online technical support, Onsite Training Onsite Inspection |

| Application: | House, Vliia, Hospital |

| Design Style: | Modern |

| Place of Origin: | Guangdong China |

| MOQ: | 200 SETS |

| Package: | White or Brown inner box, export carton |

| Lead time: | 35-40 Days |

| Factory Nature: | China Manufacturers Suppliers Factory |

Stainless Steel Cabinet Door Pulls Features:

Super corrosion resistance

This Stainless Steel Cabinet Door Pulls is made of SS304 and SS316 stainless steel, which has excellent corrosion resistance. SS304 stainless steel contains 18% chromium and 8% nickel. This combination of ingredients makes it exhibit good corrosion resistance in a variety of oxidizing acid and non-oxidizing acid environments. In the common salt spray environment test, according to the ASTM B117 standard, the handle is exposed to a 5% salt spray environment for 1000 hours, and only very slight corrosion signs appear on its surface, which is far better than ordinary metal materials. SS316 stainless steel adds 2-3% molybdenum to SS304. The addition of molybdenum significantly improves its corrosion resistance in chloride environments, and is particularly suitable for use in coastal areas or high humidity and high salt environments. For example, in the marine atmosphere environment, after a year of natural exposure test, the surface of the SS316 handle can still maintain good integrity, without obvious rust spots, effectively extending the service life of the handle.

Highly durable performance

From the perspective of material characteristics, stainless steel itself has high strength and hardness. After professional hardness testing and measurement using a Rockwell hardness tester, the Rockwell hardness of the stainless steel used in the handle can reach about HRC 20-25, which means that it can withstand large external forces without being easily deformed. In the actual tensile test, according to the ISO 5893 standard, a tensile tester was used to apply tension to the handle. The handle can withstand a tensile force of up to 1200N and the structure remains intact and functions normally. Whether it is the frequent daily operation of switching cabinet doors or the impact of large external forces in some special cases, it can ensure that the handle will not be easily damaged, providing users with a long-term and stable use experience, reducing the frequency of replacement due to handle damage, and reducing the cost of use.

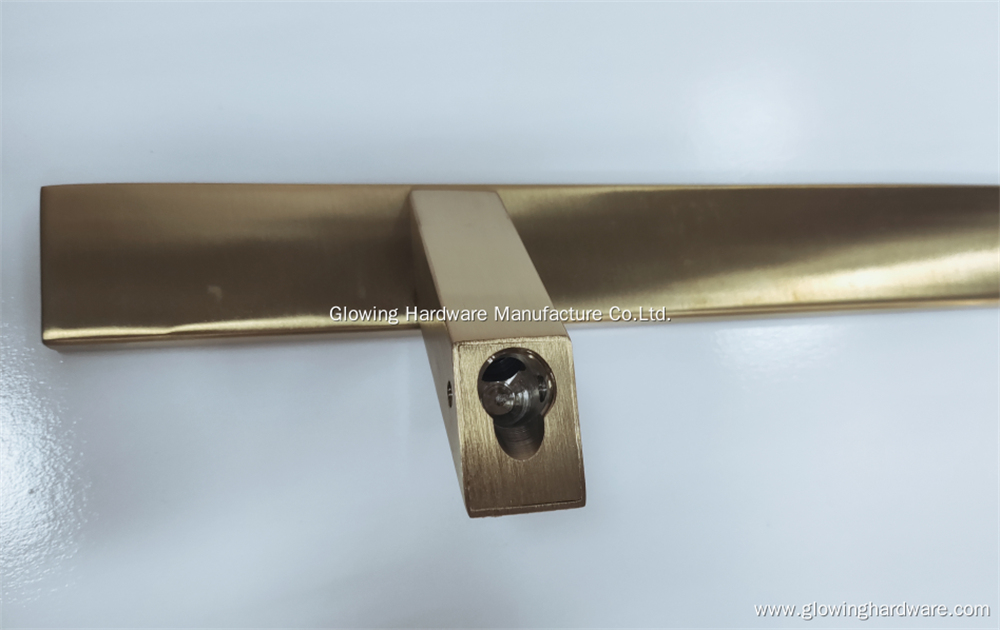

Strong and reliable structure

The handle adopts an integrated molding process, which makes the overall structure of the handle more continuous and stable. Finite element analysis (FEA) shows that the integrated molding structure can effectively disperse stress and reduce stress concentration. In the force test simulating actual use, the handle is applied with forces of different directions and magnitudes, and its maximum stress value is much lower than the yield strength of the material. At the same time, the connection between the handle and the cabinet door has been carefully designed, using oversized screws and optimized installation structures. In the vibration test, according to the ISO 16750-3 standard, the cabinet door with the handle installed was placed on a vibration test bench for high-frequency vibration. After a long period of vibration, the connection part was still tight and not loose, ensuring the stability of the handle during long-term use and avoiding safety hazards caused by loose connections.

PVD gold treatment

The handle surface is treated with PVD (physical vapor deposition) gold. This process is carried out in a vacuum environment. Through physical methods, metal titanium and other materials are deposited on the handle surface in the form of atoms or molecules to form a uniform and dense gold coating. After testing, the thickness of this coating is about 2-5μm, and the bonding force with the substrate is extremely strong. In the adhesion test, according to the ASTM D3359 standard, the cross-cut method is used for testing. The adhesion level of the coating reaches 5B, which means that the coating is almost not detached. In terms of wear resistance testing, the Taber wear tester was used to test in accordance with relevant standards. After 5,000 frictions, the coating surface was only slightly worn and still maintained a bright golden appearance. This treatment method not only improves the aesthetics of the handle, but also enhances its corrosion resistance and wear resistance.

Fine craftsmanship

During the manufacturing process, from raw material cutting to final molding, each process is strictly controlled. Using high-precision laser cutting technology, the cutting size accuracy can reach ±0.05mm, ensuring the dimensional accuracy of each part of the handle. In the molding process, advanced molds and hydraulic molding technology are used to make the shape of the handle meet the design requirements, and the fillet radius of the edge can be accurately controlled between R0.5-1mm, avoiding the possible damage to the user caused by sharp edges. The surface grinding and polishing process is even more refined. After multiple sandpaper grinding and polishing wheel treatment, the surface roughness Ra value of the handle can reach less than 0.2μm, showing a mirror-like finish. This fine process not only improves the aesthetics of the handle, but also makes it feel more comfortable during use.

Diverse surface treatments

In addition to PVD gold treatment, handles also provide a variety of surface treatments. For example, stainless steel wire drawing (SSS) forms a fine silky texture on the handle surface through mechanical friction. This treatment not only increases the texture of the surface, but also effectively hides fingerprints and minor scratches. According to tests, the friction coefficient of the surface after wire drawing is moderate, which is convenient for users to hold and not easy to be stained. Polished stainless steel treatment (PSS) makes the handle surface achieve a high gloss effect, and its glossiness can reach 800-1000GU (gloss unit), which enhances the gorgeousness of the handle. Nickel plating (SN) can improve the rust resistance of the handle, and the coating thickness is uniform. In the salt spray test, there is still no bubbling or shedding after 720 hours. Chemical polishing (CP) can make the handle surface smoother and flatter, reducing surface defects. Antique copper treatment (AB) creates a retro style, and anodizing (AC) can not only increase the surface hardness, but also present a variety of colors to meet the aesthetic and functional needs of different users.

Environmentally friendly and harmless material

Stainless steel is an environmentally friendly material that can be 100% recycled. In the production process, environmental protection standards are strictly followed, and the impact on the environment is minimal. From the perspective of chemical composition analysis, the content of harmful elements such as lead and mercury in the stainless steel material used for the handle is extremely low, far below the limit of relevant environmental protection standards. For example, the lead content is less than 0.01%, which meets the limit requirements of RoHS (Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment) on lead content. Choosing this handle is not only a pursuit of product quality, but also a contribution to environmental protection, which is in line with the concept of sustainable development in modern society.

Flexible customization service

In order to meet the personalized needs of different users, comprehensive customization services are provided. In terms of size customization, the length of the handle can be customized in the range of 100-1000mm according to the size of the cabinet door, and the diameter can also be selected between 10-50mm. Through professional design software and manufacturing technology, it can ensure that the customized handle matches the cabinet door perfectly. In terms of shape customization, a variety of designs can be provided, such as round, square, special-shaped, etc. In the customization process, advanced CNC processing equipment is used to ensure the processing accuracy of customized products. For example, for the processing of special-shaped handles, the shape accuracy error can be controlled within ±0.1mm, making each customized handle a unique work of art that meets the needs of different decoration styles and user preferences.

Stainless Steel Cabinet Door Pulls Application:

Residential kitchen cabinet door

The residential kitchen is a high-frequency space, and the cabinet door handle needs to have excellent durability and easy cleaning. This stainless steel cabinet door handle is an ideal choice for kitchen cabinet doors with its excellent corrosion resistance and wear resistance. There are often water vapor, oil stains, etc. in the kitchen environment, and the handles of ordinary materials are easily corroded and contaminated. The corrosion resistance of the stainless steel handle can resist the erosion of water vapor and oil stains, and it is not easy to rust and damage. Its surface has been specially treated, and it is not easy to be stained with oil stains and fingerprints, which is convenient for users to clean. Users only need to wipe it gently with a damp cloth to restore the handle to a clean and tidy state. At the same time, the modern design of the handle can be integrated with various kitchen decoration styles to enhance the overall aesthetics. Whether it is a simple modern style kitchen or a European classical style kitchen, this handle can be perfectly adapted to add a sense of refinement to the kitchen.

Villa wardrobe cabinet door

The villa's wardrobe is usually designed to be more luxurious and atmospheric. As an important part of the wardrobe, the cabinet door handle needs to have high-end quality to match it. This stainless steel cabinet door handle has become the first choice for villa wardrobe cabinet doors with its exquisite craftsmanship and stylish appearance. Villa wardrobes often pay attention to details and quality, and the craftsmanship and appearance of the handles directly affect the overall grade of the wardrobe. This handle adopts fine processing technology, and the surface treatment is smooth and delicate, with full texture. Its stylish appearance design can complement the luxurious style of the villa wardrobe and enhance the overall beauty of the wardrobe. At the same time, its customization service can meet the personalized needs of the villa wardrobe. Villa owners usually have unique design requirements for wardrobes. The customization service of the handle can be personalized according to the size, color and style of the wardrobe to create a unique wardrobe style.

Hospital locker door

The hospital is a place with extremely high requirements for hygiene and safety. The locker door handle needs to be easy to clean, corrosion-resistant and antibacterial. This stainless steel cabinet door handle is convenient for hospital staff to clean and disinfect with its smooth surface and excellent corrosion resistance. There are a large number of bacteria and viruses in the hospital environment, and the locker door handle is a place where bacteria are easily bred and spread. The surface of the stainless steel handle is smooth, not easy to hide dirt, and convenient for cleaning staff to wipe and disinfect with disinfectants. Its excellent corrosion resistance can resist the corrosion of disinfectants and maintain the performance and appearance of the handle. At the same time, the solid structure of the handle can withstand frequent use and ensure the stability and safety of the locker door under frequent opening and closing. Hospital lockers are opened and closed many times a day. The durability and firmness of the handle can ensure its long-term stable operation and avoid affecting the normal use of the locker due to damage to the handle. This is very important for places such as hospitals that have extremely high requirements for hygiene and safety.

Office file cabinet door

Office file cabinets are places where important documents and materials are stored. The cabinet door handles need to be durable and beautiful. This stainless steel cabinet door handle has become an ideal choice for office file cabinet doors with its simple design and excellent durability. In the office environment, the frequency of use of file cabinets is high, and the handles need to be able to withstand frequent opening and closing operations. This handle is made of high-quality stainless steel and has been precisely processed. It has excellent durability and can be used for a long time without deformation or damage. Its simple design style meets the requirements of the office environment, is not too ostentatious, and can be integrated with the overall decoration style of the office. For example, in a modern minimalist office, the simple design of this handle can complement the overall style and enhance the beauty of the office environment. Moreover, the easy cleanability of the handle also facilitates office staff to maintain it in daily use and keep the filing cabinet tidy.

Hotel bathroom cabinet door

The hotel bathroom is a humid environment, and the corrosion resistance and waterproof performance of the cabinet door handle are high. This stainless steel cabinet door handle has become the first choice for hotel bathroom cabinet doors with its excellent corrosion resistance and waterproof performance. There are often water vapor and water droplets in the bathroom, and the handles of ordinary materials are prone to rust and corrosion. The corrosion resistance and waterproof performance of the stainless steel handle can effectively resist the erosion of water vapor and water droplets, and maintain the performance and appearance of the handle. Its surface has been specially treated and is not easy to get wet. Even if water drops fall on the handle, it can slide off quickly and will not penetrate into the handle. At the same time, the comfortable grip and smooth opening and closing experience of the handle provide hotel guests with a convenient use experience. When using the bathroom cabinet, guests can easily hold the handle and smoothly open and close the cabinet door, which improves the guest's stay experience.

Commercial display cabinet doors

Commercial display cabinets are important places for displaying goods, and the cabinet door handles need to have the function of attracting customers' attention and improving the grade of goods. This stainless steel cabinet door handle has become an ideal choice for commercial display cabinet doors with its stylish appearance and exquisite craftsmanship. In commercial places, the appearance of the display cabinet directly affects the sales of goods. The stylish appearance of this handle can attract customers' attention and make it easier for customers to pay attention to the goods in the display cabinet. Its exquisite craftsmanship and high-quality materials can improve the grade of goods and make customers feel that the goods are more high-end and reliable. At the same time, the customized service of the handle can be personalized according to the size and style of the display cabinet. The size and style of commercial display cabinets vary. The customized service can make the handle better match the display cabinet and create a unique display effect. For example, for some high-end brand display cabinets, handles with brand characteristics can be customized to enhance the brand recognition and display effect.

Stainless Steel Cabinet Door Pulls Maintenance:

Clean the surface regularly

Wipe the surface of stainless steel cabinet door pulls with a soft cloth regularly is an important measure to maintain its appearance and performance. The soft cloth is soft in texture, will not scratch the surface of the handle, and can effectively remove dust and dirt. During the cleaning process, avoid using detergents containing acidic or alkaline ingredients, because these detergents may corrode the coating on the surface of the handle, affecting its beauty and corrosion resistance. For example, some strong acidic detergents may react with the oxide film on the surface of stainless steel, destroying the protective effect of the oxide film. After cleaning, wipe the surface moisture with a dry cloth to prevent water stains from remaining. Water stains may cause water stains and affect the beauty of the handle. In humid environments, such as bathrooms and kitchens, the cleaning frequency should be increased to keep the handle dry and clean. Humid environments are prone to breed bacteria and dirt. Timely cleaning can prevent dirt accumulation and maintain the hygiene and performance of the handle.

Avoid scratching with hard objects

It is very important to avoid scratching the surface of the handle with hard or sharp objects. Scratches from hard or sharp objects may damage the coating on the handle surface or leave scratches, affecting its aesthetics and corrosion resistance. During the cleaning process, a soft cloth or sponge should be used to gently wipe the surface. If there are slight scratches on the surface, professional polishing agents can be used to repair them. Professional polishing agents can fill scratches and restore the gloss of the handle surface. However, it should be noted that the use of polishing agents should be appropriate to avoid excessive use that may damage the surface coating. In daily use, users should also be reminded to avoid contact with hard objects to prevent accidental scratches. For example, when carrying items, be careful to avoid collisions between items and handles to protect the surface of the handles.

Regularly check the tightening

Regularly checking whether the connection between the handle and the cabinet door is tight is the key to ensuring the safety and reliability of the handle. If looseness or falling off is found, the screws should be tightened in time or the damaged parts should be replaced. During the inspection, tools such as screwdrivers can be used to check the tightness of the screws. If the screws are loose, they should be tightened according to the specified tightening force. During the tightening process, appropriate tools should be used to avoid excessive force that may cause the screws to slip or damage the cabinet door. If the screws or nuts are found to be damaged, they should be replaced in time to ensure the stability of the connection. Regular inspections can detect potential safety hazards in time and avoid accidental injuries caused by loose or falling handles. For example, in public places, if the handle is loose, it may cause injuries to the user. Regular inspections can eliminate this safety hazard in time.

Prevent chemical corrosion

Avoiding long-term contact of handles with chemicals is an important measure to protect handles. Chemical substances such as acids, alkalis, and salts may corrode the surface of the handles, affecting their appearance and service life. If you accidentally come into contact with chemicals, rinse them immediately with clean water and wipe them dry with a dry cloth. For example, in a kitchen environment, you may come into contact with some acidic detergents or alkaline detergents. After use, you should clean the residue on the surface of the handle in time to prevent chemical corrosion. In an industrial environment, if the handle is exposed to gases or liquids containing chemicals, appropriate protective measures should be taken, such as installing a protective cover, etc., to reduce the contact between the chemical substances and the handle. Preventing chemical corrosion can maintain the appearance and performance of the handle and extend its service life.

Regular lubrication activities

For handles with moving parts, such as rotatable or sliding handles, lubricating oil or grease should be applied regularly to keep them running smoothly. Lubricating oil or grease can reduce friction between moving parts, reduce wear and extend the service life of the handle. During the lubrication process, an appropriate amount of lubricant should be used to avoid excessive lubricant dripping or contaminating the cabinet door. A small brush or dropper can be used to evenly apply the lubricant to the moving parts. The frequency of regular lubrication can be determined according to the use of the handle. It is generally recommended to perform lubrication maintenance every six months. Through regular lubrication, it can be ensured that the moving parts of the handle are always flexible, providing users with a smooth use experience.

Avoid high temperature exposure

Avoiding long-term exposure of handles to high temperatures or direct sunlight is an important part of protecting handles. High temperatures may cause the surface coating of the handle to fade or deform, affecting its appearance and performance. Ultraviolet rays in the sun may accelerate the aging of the coating and make it lose its luster. During the installation process, a cool and ventilated location should be selected to avoid direct sunlight. If a high temperature environment cannot be avoided, shading measures can be taken, such as installing sunshades or curtains. For example, the cabinet door handle on the balcony may be exposed to direct sunlight. Installing a sunshade can effectively reduce the exposure of the handle to sunlight. Avoiding high temperature exposure can maintain the appearance and performance of the handle, making it beautiful and stable for a long time.