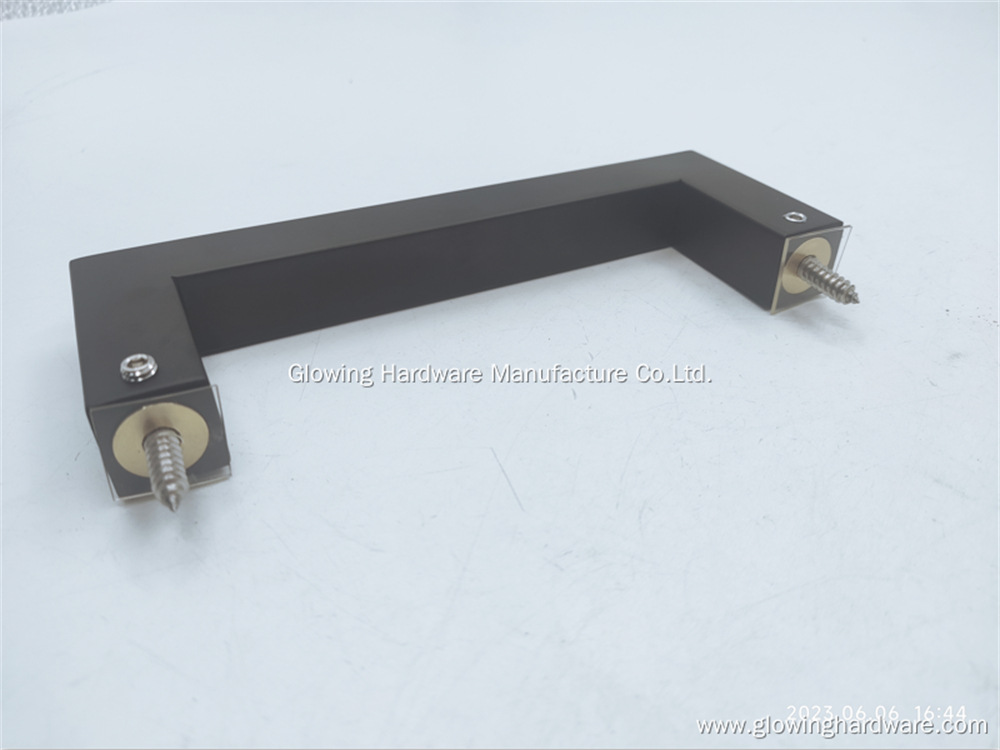

Stainless Steel Kitchen Cupboard Door Handles

- Product Information

Stainless Steel Kitchen Cupboard door handles are a type of hardware used for kitchen cupboard door panels to achieve the opening and closing functions of cupboard doors. They are usually made of stainless steel, which is durable and corrosion-resistant. This handle has a simple and modern design, smooth lines, and a finely processed surface, showing the unique luster and texture of metal. After it is installed on the cupboard door, users can open or close the cupboard door by easily holding the handle and applying appropriate pulling force. It is easy to operate and feels comfortable, adding a simple yet elegant beauty to the kitchen space.

Stainless Steel Kitchen Cupboard Door Handles Parameters:

| Model Number: | HFP003 |

| Product name: | Stainless steel door pull handle |

| Material: | SS304 / SS316 |

| Handle size: | Customized |

| Tube diameter: | Customized |

| Finish: | SSS/PSS/PVD/SN/CP/AB/AC/customized |

| After-sale Service: | Online technical support, Onsite Training Onsite Inspection |

| Application: | House, Vliia, Hospital |

| Design Style: | Modern |

| Place of Origin: | Guangdong China |

| MOQ: | 200 SETS |

| Package: | White or Brown inner box, export carton |

| Lead time: | 35-40 Days |

Materials of Stainless Steel Kitchen Cupboard Door Handles

Material: The handle is crafted from high-quality stainless steel, ensuring durability and resilience.

Finish: The matte black finish offers a sleek and modern look.

Colour Comparison: Matte black, as a shade, is identical to regular black in colour.

Reflective Properties: Unlike normal black finishes that reflect light and have a glossy appearance, matte black is non-reflective and lacks any gloss.

Popularity: The matte black surface is highly sought-after globally, adding to the handle's appeal.

Installation of Stainless Steel Kitchen Cupboard Door Handles

Preparation

Gather all necessary tools, including a screwdriver (either flathead or Phillips, depending on the screws provided with the handles), measuring tape, and a pencil.

Ensure that you have the correct handles for your cupboard doors and that they match the screws provided.

Measurement

Measure the distance between the screw holes on the cupboard door and mark the positions on the door with a pencil.

Ensure that the handles are positioned correctly and level before marking the screw holes.

Installation

Line up the handles with the marked screw holes and use the screwdriver to secure them in place.

Avoid overtightening the screws, as this could strip the threads or damage the cupboard door.

Final Check

Once all handles are installed, open and close the cupboard doors to ensure that they function smoothly and that the handles are securely fastened.

Stainless Steel Kitchen Cupboard Door Handles Features

1. Excellent corrosion resistance

After rigorous salt spray testing, SS304 Stainless Steel Kitchen Cupboard Door Handles can withstand 240-480 hours of rust-free performance in a neutral salt spray environment; SS316 door handles can withstand 360-600 hours of corrosion-free performance. This shows that they can effectively resist the effects of common corrosive factors such as moisture and detergent residues in the kitchen environment. In actual use, kitchen cupboard door handles are often exposed to water, oil, and various chemical detergents, but the high-quality stainless steel material and fine surface treatment process keep the surface as bright as new, without worrying about damage caused by corrosion.

2. Super strong stability

The design and manufacture of the door handle focuses on stability, and the connection part with the cupboard door panel adopts a sturdy mounting structure. Usually equipped with high-quality screws and nuts, these fasteners are precisely processed with high dimensional accuracy, and perfectly match the mounting holes of the door handle and cupboard door panel. The installed door handle has a strong pulling force bearing capacity. It has been tested to withstand a pulling force of 50-80N without loosening or falling off. This means that even if the user frequently pulls hard during use, the door handle can always remain stable and firm, without shaking or falling, providing reliable protection for the opening and closing of the cabinet door.

3. Convenient and easy installation

The installation process of the door handle is simple and easy, without complicated professional tools and skills. Its design fully considers the user's installation convenience, and usually adopts standardized installation hole spacing and size, which is compatible with the specifications of most cabinet door panels. During installation, the user only needs to follow the instructions of the manual, use common tools such as screwdrivers, align the door handle with the installation hole, and tighten the fastening screws in sequence to complete the installation. The entire installation process can generally be completed within 10-15 minutes, and even users without professional installation experience can easily do it, greatly saving installation time and cost.

4. Customized size design

The door handle provides customized size services to meet the installation needs of different cabinet door panels. Common standard lengths include 150mm, 200mm, 250mm, 300mm, etc. The width is generally between 20-30mm and the thickness is about 8-12mm. In addition, users can also customize door handles of specific length, width and shape from manufacturers according to their cabinet door size and design style. The customized size design ensures the perfect fit between the door handle and the cabinet door panel, avoiding installation difficulties or visual inconsistency caused by inappropriate size, and providing users with a more personalized and precise installation solution.

5. Exquisite surface treatment process

The surface treatment process of Stainless Steel Kitchen Cupboard Door Handles is exquisite. Common treatment methods include SSS (sanded stainless steel color), PSS (polished stainless steel color), PVD (physical vapor deposition), SN (brushed nickel color), CP (brushed chrome color), AB (brushed black bronze color), AC (brushed copper color) and customized treatment. Take PVD surface treatment as an example. Its process is to deposit metal or metal compound on the surface of the handle under vacuum conditions to form a uniform and dense coating with a coating thickness of up to 3-5 microns. This not only significantly improves the wear resistance of the handle, making its surface hardness reach HV1800-2200, but also gives a rich color selection to meet the aesthetic needs of different users and the matching of kitchen decoration styles. At the same time, these surface treatment processes have passed friction and corrosion tests to ensure that the surface treatment layer is not easy to wear, fade or peel off during long-term use, and always maintains a beautiful appearance.

6. High-precision processing technology

Stainless Steel Kitchen Cupboard Door Handles are manufactured using high-precision processing technology to ensure that the product meets high standards in terms of dimensional accuracy, shape accuracy and surface roughness. Its processing process usually includes advanced processes such as laser cutting, precision stamping, and CNC processing, and the processing accuracy can be controlled within ±0.1mm. During the cutting and forming process, it can ensure that the edges of the door handles are neat and smooth, without burrs and irregular shapes. At the same time, the surface roughness is low and the touch feels comfortable. After fine grinding and polishing, the surface gloss is high and the reflection effect is good, which further enhances the overall texture and aesthetics of the product.

Application Scenarios of Stainless Steel Kitchen Cupboard Door Handles

1. Modern Family Kitchen

In modern family kitchens, Stainless Steel Kitchen Cupboard Door Handles are key accessories to enhance the overall beauty and practicality of the cabinets. As people pay more attention to kitchen decoration, more and more families choose simple and modern style cabinet designs, and the appearance of this door handle is perfectly matched with them. Its diverse surface treatment methods can meet the decoration style needs of different families. Whether it is the cold texture of the original color of stainless steel or the warm copper color after PVD treatment, it can add a fashionable atmosphere to the kitchen. According to statistics, in modern family kitchen decoration, about 75% of families will choose stainless steel cabinet door handles, because it is not only beautiful, but also easy to clean and durable. In daily use, even if the kitchen environment is relatively humid, the door handle is not easy to rust, and the surface is smooth, which is very convenient to wipe. It can keep bright and new for a long time, which reduces a lot of burden for housewives' daily cleaning work.

2. High-End Villa Kitchen

In the kitchen design of high-end villas, Stainless Steel Kitchen Cupboard Door Handles are an important element to show the overall quality and luxury of the kitchen. Villa kitchens are usually large in area, and the design of cabinets pays more attention to details and quality. The exquisite craftsmanship and high-end materials of this door handle can complement the overall kitchen decoration style. Its customized size service enables the door handle to perfectly fit cabinets of various styles and sizes. Whether it is a European classical style or a modern minimalist style kitchen, the overall style can be unified by choosing the appropriate door handle surface treatment method. In addition, the corrosion resistance and durability proven by salt spray test and wear test ensure the consistent stability and beauty of the door handle during long-term use, providing high-quality use experience for high-end villa owners and enhancing the overall value of the kitchen.

3. Hospital Kitchens

As a special application scenario, hospital kitchens have extremely high requirements for the hygiene and durability of cabinet door handles. Stainless Steel Kitchen Cupboard Door Handles are an ideal choice for hospital kitchens because of their antibacterial and easy-to-clean properties. SS304 or SS316 stainless steel materials have natural antibacterial properties and can effectively inhibit the growth of bacteria, which is crucial for hospital kitchens, which have extremely high hygiene requirements. At the same time, the door handle surface is smooth and seamless, and it is not easy to hide dirt. Cleaning staff only need to wipe it with clean water or mild detergent to restore the brightness, reducing the investment of cleaning time and energy. In actual use, the cabinet door handles of hospital kitchens need to withstand a large number of usage frequencies every day, but after professional testing, high-quality door handles can withstand up to 1,000 times of tensile and pressure tests without damage, ensuring the stability and reliability of the opening and closing of the hospital kitchen cabinet doors, and providing strong guarantees for the daily operation of the hospital.

4. School Canteen Cabinet

The cabinet facilities of the school canteen need to be durable and easy to maintain to meet the challenges brought by the daily use of a large number of students. Stainless Steel Kitchen Cupboard Door Handles have become an ideal accessory for school canteen cabinets with their sturdy and durable characteristics. The high-quality stainless steel material used can withstand frequent pulling and collisions, and can maintain stable performance and good appearance even in high-intensity use environments. At the same time, the ease of installation and stability of the door handles also bring great convenience to the installation and maintenance of the cabinets in the school canteen. During the installation process, it can be completed quickly without the need for professionals, saving installation costs and time. Its stable installation structure can ensure that the door handle will not loosen or fall off when students frequently use the cabinet door, effectively avoiding the problem of the cabinet door being unable to open and close normally due to damage to the door handle, and ensuring the normal operation order of the school cafeteria.

5. Commercial Kitchen Cabinet

In commercial kitchens, Stainless Steel Kitchen Cupboard Door Handles are widely used in the matching of various cabinet facilities. The work intensity of commercial kitchens is high, and the cabinet door handles need to have extremely high durability and reliability. After professional testing, high-quality stainless steel door handles can withstand a tensile force of 50-80N without loosening or damage, which can fully meet the requirements of high-intensity use in commercial kitchens. In addition, the corrosion resistance of the door handle enables it to maintain a good working condition and appearance when facing various detergents, grease and water vapor in the kitchen environment. Its diverse surface treatment methods can also be coordinated with the overall decoration style of commercial kitchens to enhance the overall image of the kitchen. Whether it is a commercial kitchen in a restaurant, hotel or corporate canteen, installing Stainless Steel Kitchen Cupboard Door Handles can not only increase the service life of the cabinet, but also provide a more convenient and comfortable use experience for kitchen staff and improve work efficiency.

6. Marine ship kitchen cabinets

In the kitchen environment of marine ships, the space is limited and the humidity is high, which puts more stringent requirements on the material and performance of the cabinet door handles. Stainless Steel Kitchen Cupboard Door Handles are an ideal choice for marine ship kitchens with their excellent corrosion resistance and stability. The high salt and high humidity conditions in the marine environment can easily cause door handles made of ordinary materials to rust and damage, but the SS316 stainless steel door handles have been proven by professional salt spray tests to be able to maintain good performance and appearance for a long time in a high-salt environment. At the same time, the compact design and stable installation structure of the door handle prevent it from loosening or falling off even if it encounters bumps and shaking during the voyage of the ship. This is crucial to ensure the normal operation of the ship's kitchen. In addition, the easy-to-clean and antibacterial properties of the door handle also meet the strict requirements of marine ship kitchens for hygiene and maintenance, providing a clean and hygienic working environment for the crew.

Stainless Steel Kitchen Cupboard Door Handles Maintenance

1. Daily cleaning and wiping

Regular cleaning and wiping of Stainless Steel Kitchen Cupboard Door Handles is the key to maintaining their beauty and performance. It is recommended to use a soft dry cloth or a slightly damp cotton cloth to clean 1-2 times a week. When cleaning, focus on wiping the surface, edges and installation parts of the handle to remove dust, stains and fingerprints on the surface. For stubborn stains, a neutral detergent can be used for cleaning. Dilute the detergent with water in a ratio of 1:10, dip a soft cloth in it and gently wipe the stain, then rinse with clean water and wipe dry. Avoid using detergents that are too acidic or alkaline, as well as cleaning tools with rough particles, to avoid scratching the surface treatment layer. For example, some detergents containing hydrochloric acid cannot be used to clean door handles. Their pH value may be lower than 1, which will cause corrosive damage to the surface treatment layer, affecting the appearance and service life of the door handles. The correct cleaning method can not only keep the door handles bright and beautiful, but also effectively prevent bacteria growth and corrosion problems caused by dirt accumulation, and extend the service life of the door handles.

2. Check fasteners regularly

Regularly checking the fasteners of Stainless Steel Kitchen Cupboard Door Handles is a necessary step to ensure that they are firmly installed and work stably. It is recommended to check the installation bolts, nuts and other fasteners of the door handles once a quarter. During the inspection, first observe whether the fasteners are loose, falling off or rusted. If the fasteners are found to be loose, they should be tightened with appropriate tools in time, but care should be taken to avoid damage to the fasteners or door handles due to over-tightening. For rusted fasteners, rust removal should be carried out first. Special rust removers or tools such as wire brushes can be used to remove rust on the surface, and then anti-rust grease should be reapplied and tightened. If the fasteners are severely damaged and cannot be used anymore, new qualified fasteners should be replaced. By regularly checking and maintaining fasteners, problems such as door handle displacement and cabinet door loosening caused by loose or damaged fasteners can be effectively prevented, ensuring that the door handles always maintain a stable installation state during long-term use and guaranteeing the normal opening and closing function of the cabinet doors.

3. Lubricate the moving parts

Regularly lubricate the moving parts of the Stainless Steel Kitchen Cupboard Door Handles to maintain their operational flexibility and extend their service life. It is recommended to lubricate the moving parts every six months. First, close the cabinet door and remove the decorative cover of the door handle (if any) to expose the internal moving parts such as the shaft and connecting rod. Drop a small amount of food-grade lubricant, such as silicone oil, on the friction surface of these moving parts. The amount of lubricant should cover the friction surface and not flow. Then pull the door handle several times to evenly distribute the lubricant between the moving parts. Finally, reinstall the decorative cover, open the cabinet door, and test the operating performance of the door handle. By regularly lubricating the moving parts, the friction and wear between the parts can be effectively reduced, and the problems of loose parts and poor operation caused by long-term friction can be prevented, ensuring that the door handle is pulled smoothly, providing users with a more convenient use experience.

4. Prevent chemical corrosion

In the kitchen environment, door handles should be kept away from corrosive chemicals for a long time to prevent corrosion of their surface treatment layer and stainless steel material. For example, avoid direct contact of door handles with strong acidic or alkaline detergents, bleaches and other chemicals. If these chemicals are needed when cleaning the kitchen, it is recommended to dilute them to a safe concentration first, and rinse the door handles with clean water immediately after cleaning, and wipe them dry with a dry cloth. At the same time, when storing chemicals in the kitchen, ensure that their containers are well sealed and away from hardware accessories such as door handles to avoid damage caused by chemicals remaining on the door handles after evaporation. In addition, reducing the contact of door handles with salt, oil and other substances in the kitchen can also help extend their service life. After each cooking, you can gently wipe the door handles with a damp cloth to remove oil stains and salt residues on the surface.

5. Repair surface damage in time

During use, the surface of stainless steel kitchen cupboard door handles may be scratched, pitted and other damages due to accidental collisions, scratches and other reasons. These surface damages will not only affect the aesthetics of the door handles, but may also become the starting point of corrosion, thereby affecting the overall performance and service life of the door handles. Therefore, once the surface of the door handle is slightly damaged, it should be repaired in time. For shallow scratches, special metal polishing agent and fine sandpaper can be used for polishing. First, use fine sandpaper to gently polish the scratches to make the surface relatively flat, then apply an appropriate amount of metal polishing agent and wipe repeatedly with a soft cloth until the scratches disappear or become less obvious. For deep scratches or pit damage, it is recommended to contact professional maintenance personnel for repair or replacement of damaged parts. During the repair process, the material and surface treatment process requirements of the door handle should be strictly followed to ensure that the surface quality of the repaired door handle meets the standards to maintain its good anti-corrosion performance and appearance.

6. Regularly check the anti-corrosion coating

Regularly checking the anti-corrosion coating of Stainless Steel Kitchen Cupboard Door Handles is an important maintenance measure to ensure its long-term and stable use. It is recommended to conduct a comprehensive inspection of the anti-corrosion coating of the door handle every six months. During the inspection, carefully observe whether the coating surface is peeling, cracking, fading, etc. If the coating is found to be partially peeling or cracking, it should be repaired in time. You can use anti-corrosion coatings that match the original coating material for local repairs. First, clean the damaged area to remove rust and dirt on the surface, then apply the anti-corrosion coating and let it dry and cure. For large areas of fading or aging, it is recommended to re-treat the surface or replace the door handle parts. Regular inspection and maintenance of the anti-corrosion coating can effectively prevent the exposure and corrosion of the metal substrate caused by coating damage, ensuring the beautiful appearance and stable performance of the door handle in long-term use.