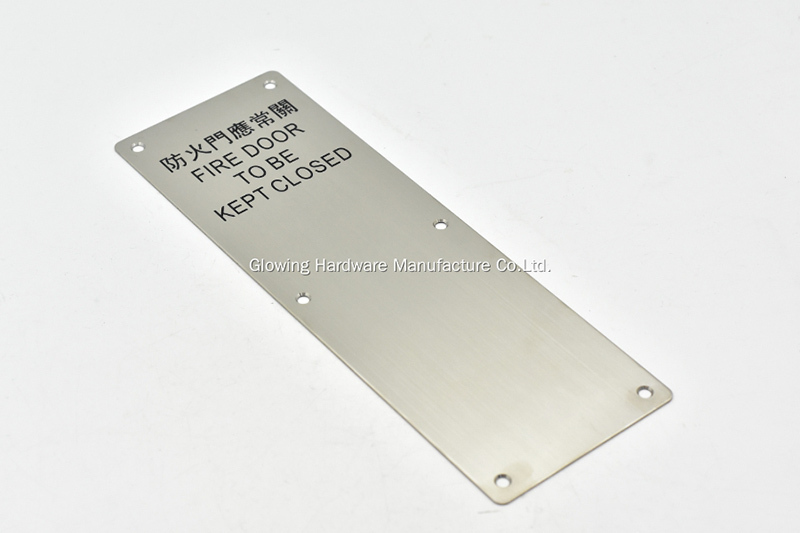

Stainless Steel Push Plate for Door

- Product Information

Stainless Steel Push Plate for Door is a very effective door signal method installed on the surface of the door body and provides special instructions to the user. Its core function is to reduce the wear caused by direct contact with the door surface by providing a flat force point, while improving the durability and aesthetics of the door body. The two main technologies used to add appropriate text and patterns to the push and pull signs include screen printing and etching. Screen printing is by far the cheapest of such methods, and the results are clear and sharp.

Stainless Steel Push Plate for Door Parameters:

| Model | DS002 |

| Product Name | Stainless Steel Sign Plate |

| Material | Stainless Steel 304 or 316 |

| Size | 100×100×1.5mm / 300×100×2.0mm or Customized |

| Finish | SSS/PSS/PVD/SN/CP/AB/ACM/PB/SB/Customized |

| After-Sale Service | Online technical support, Onsite Training, Onsite Inspection |

| Application | Office, Restaurants, Schools, Shopping Malls, Shops, Gyms |

| Design Style | Modern |

| Place Of Origin | Guangdong, China |

| MOQ | 200pcs |

| Package | White or Brown inner box, export carton |

| Lead Time | 30-35 Days |

Stainless Steel Push Plate for Door Technology and Features

1. Technology

Material selection: 304 or 316L stainless steel plates are used, with a thickness of 1.5mm-3mm, to ensure strength and corrosion resistance.

Surface treatment: Through polishing, brushing or sandblasting, mirror, matte or anti-slip textures are formed, taking into account both beauty and functionality.

Structural design:

Fixed method: Fixed to the door body by hidden screws or adhesives to avoid exposed screws affecting the appearance.

Edge treatment: Rounded or chamfered design is adopted to prevent scratches on users.

Drainage design: Drainage grooves are set at the bottom of some products to avoid corrosion caused by water accumulation.

2. Core features

Corrosion resistance: Stainless steel materials can resist acid, alkali, salt spray and humid environments, and are suitable for scenes such as seaside and industrial areas.

High strength: The load-bearing capacity is more than 50kg, which meets the needs of high-frequency use.

Antibacterial property: The surface is smooth and not easy to hide dirt and dirt, which meets the hygiene standards of the medical and food industries.

Easy to clean: Stains can be removed by wiping with a damp cloth, and the maintenance cost is low.

Customization: Supports laser cutting and etching patterns to meet personalized design needs.

Stainless Steel Push Plate for Door Application Scenarios

1. Commercial buildings

Application scenarios: Glass doors and revolving doors in shopping malls, hotels, office buildings and other places.

Solution:

Reduce wear and tear: Replace traditional handles to avoid door scratches caused by frequent pushing and pulling.

Enhance image: Mirror polished push plates are matched with glass doors to enhance the sense of transparency and modernity of the space.

Case: The lobby of a five-star hotel uses 316L stainless steel push plates, combined with an automatic induction door system, with an average daily use of more than 2,000 times, and no damage for three years.

2. Public facilities

Application scenarios: Barrier-free passages in hospitals, schools, and subway stations.

Solution:

Anti-slip design: The brushed surface push plate provides friction to facilitate the passage of wheelchairs and strollers.

Antibacterial requirements: Meet medical-grade stainless steel standards to reduce the risk of cross-infection.

Case: A tertiary hospital in Beijing installed anti-slip push plates in the ward building, combined with automatic sliding doors, and patient satisfaction increased by 40%.

3. Industrial field

Application scenarios: explosion-proof doors and fire doors in factories and warehouses.

Solution:

High temperature resistance: 316L material can withstand extreme temperatures from -196℃ to 800℃.

Anti-static: The surface resistivity is less than 10⁶Ω, avoiding safety hazards caused by static electricity.

Case: A chemical company warehouse uses explosion-proof push plates, which have passed ATEX certification and effectively reduce the risk of explosion.

4. High-end residences

Application scenarios: entrance doors and balcony doors of villas and apartments.

Solution:

Personalized design: Etching the owner's name, LOGO or decorative pattern to improve the door body recognition.

Anti-theft function: Linked with smart door locks, hidden installation enhances security.

Case: A high-end villa project in Shanghai customized laser engraved push plates, combined with fingerprint locks, and the owner's satisfaction reached 98%.

5. Special environment

Application scenario: seaside resort, salt spray industrial zone.

Solution:

Salt spray resistance: 316L material contains molybdenum, and its corrosion resistance is 3 times higher than that of 304.

Long life: After more than 2000 hours of neutral salt spray test (NSS), there is no rust on the surface.

Case: A resort in Hainan uses salt spray resistant push plates, and the maintenance cost is reduced by 60% within five years.

Maintenance and maintenance of Stainless Steel Push Plate for Door

Daily cleaning: Use neutral detergent and soft cloth to wipe, avoid using steel wool or strong acid and alkali solvents.

Regular inspection: Check whether the fixing screws are loose every quarter, and replace them in time if rust is found.

Rust prevention: If there is slight rust on the surface, it can be polished and restored with stainless steel special cleaning paste.

Extreme environment: It is recommended to apply anti-rust wax every six months in the seaside or industrial area to extend the service life.

Stainless Steel Push Plate for Door FAQs

Q1: How to choose the right material for door push plates?

A: Choose according to the use environment: 304 stainless steel can be selected for indoor environment, and 316L is recommended for outdoor or high-corrosion environment.

Q2: Does it support customized patterns?

A: It supports laser engraving, etching and other processes, and the minimum order quantity is usually more than 100 pieces.

Q3: Will the installation method damage the door body?

A: It is fixed with hidden screws or adhesives, without drilling, to protect the integrity of the door body.