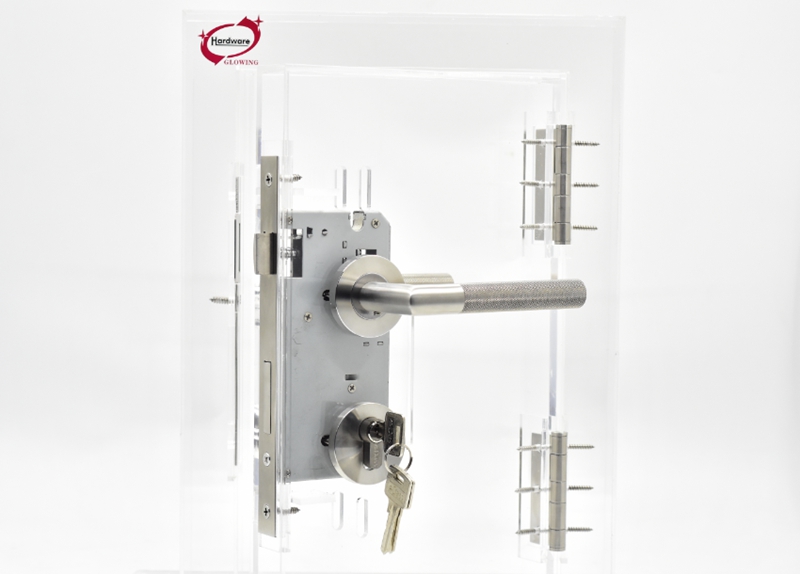

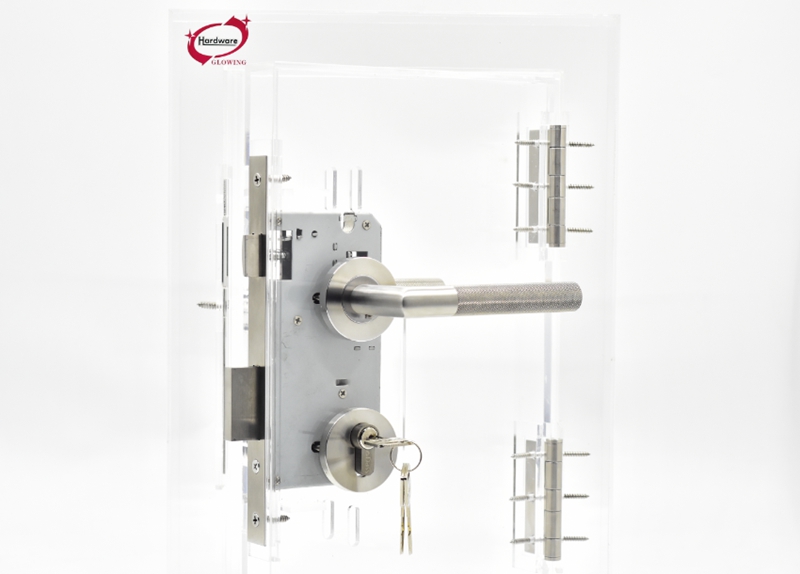

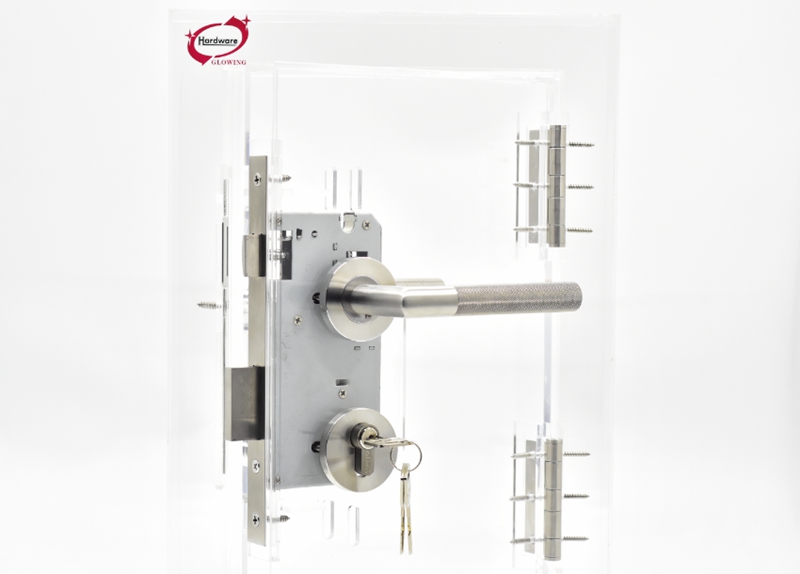

Knurled Lever Door Handles

- Product Information

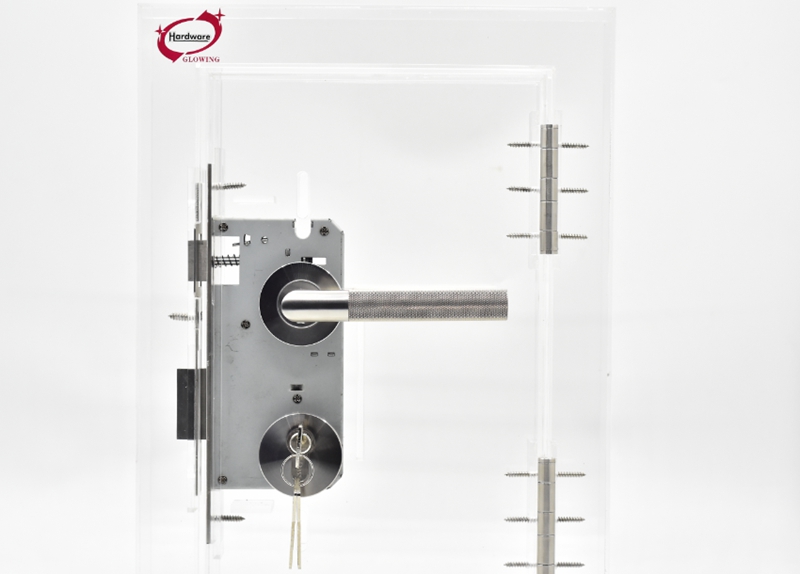

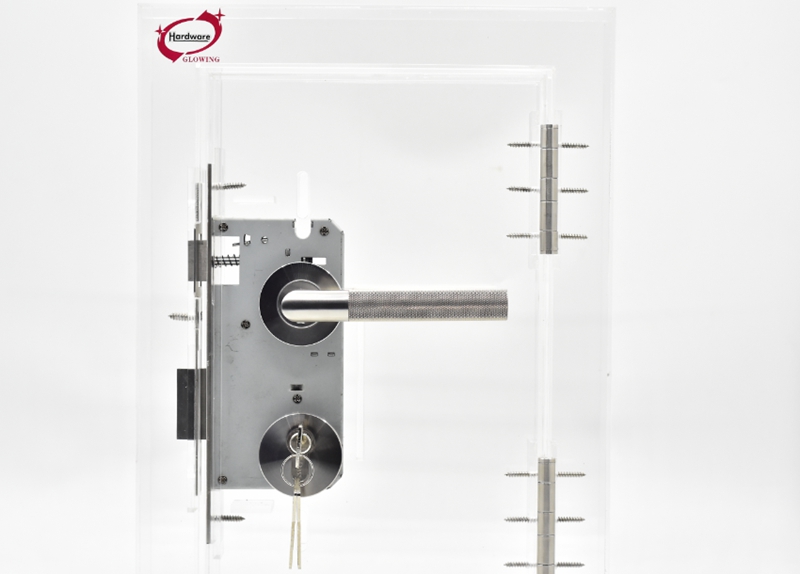

Knurled lever door handles are a type of lever door handle device with a knurled design. It is mainly made of stainless steel, with common materials being SS304 and SS316, both of which have good corrosion resistance and mechanical properties. The device includes a lever handle with a knurled texture, a lock cylinder, a lock body, and related installation accessories. The handle part is designed with a knurled texture, which can increase friction, making the user's grip more stable and more convenient when opening and closing the door. When using it, the user only needs to gently hold the handle, apply appropriate pressure and rotate it to easily open or close the door lock. The operation is simple and comfortable.

Knurled Lever Door Handles Parameters:

| Model | HS042 |

| Product Name | tainless steel solid door handle |

| Material | SS304 / SS316 |

| Handle Size | According to the sample or drawing |

| Rosette size | φ53×9mm |

| Finish | SSS/PSS/PVD/SN/CP/AB/ACM/PB/SB/Customized |

| After-sale Service | Online technical support, onsite training, onsite inspection |

| Application | House, Vliia, Hospital |

| Design Style | Modern |

| Place Of Origin | Guangdong, China |

| MOQ | 300 sets |

| Package | White or Brown inner box, export carton |

| Delivery Time | 35-40 Days |

Knurled Lever Door Handles Features:

Corrosion-resistant and durable materials

Knurled lever door handles are mainly made of SS304 or SS316 stainless steel. SS304 stainless steel has good corrosion resistance and can resist most common corrosive substances, such as acid rain, seawater, etc. Its corrosion resistance can reach more than 10 years in general environments. SS316 stainless steel adds molybdenum elements on the basis of SS304, which further enhances its ability to resist pitting corrosion and crevice corrosion. When used in marine or chemical environments, its corrosion resistance life can be extended to more than 15 years. The hardness of these two materials is above HV200, with high strength and toughness, which can effectively resist external impact and wear, ensuring that the door handle maintains good performance and appearance during long-term use.

Precise size adaptation

The specifications and dimensions of the Knurled Lever Door Handles are reasonably designed and can be customized according to the samples or drawings provided by customers. The base size is φ53×9mm. This size design can be adapted to most standard door bodies, and the installation is convenient and stable. After precise machining, the dimensional accuracy of each component can be controlled within ±0.1mm, ensuring the close fit between the door handle and the door body and lock body, avoiding looseness and shaking. This precise dimensional control not only improves the installation quality of the door handle, but also enhances its stability and safety during use.

Diverse surface treatments

Provide a variety of surface treatment processes, including SSS, PSS, PVD, SN, CP, AB, ACM, PB, SBand customized treatments. Among them, the PVD process can make the surface hardness reach HV3000 or above, with good wear resistance and corrosion resistance, and can maintain the surface gloss and color even under frequent use and harsh environments. For example, after 500 dry-wet alternating salt spray tests, the PVD-treated door handle showed no obvious signs of corrosion on the surface, while untreated stainless steel door handles may show corrosion such as rust spots under the same test conditions, which fully proves the superiority of its surface treatment.

Humanized handle design

The handle part adopts a knurled design, which not only increases the aesthetics of the handle, but more importantly, increases the friction when the user holds it. The depth and density of the knurled texture are carefully designed to increase the friction coefficient by about 30%, effectively preventing the unstable grip caused by wet or greasy hands. At the same time, the shape of the handle conforms to the principles of ergonomics, and its curvature and thickness design can naturally fit the palm of the hand, making the user more comfortable and labor-saving when operating. After a large number of door opening and closing operations, the user will still not feel hand fatigue, which improves the user experience.

The lock core is safe and reliable

Equipped with high-quality lock core, the lock core adopts a multi-track pin structure, the internal pins and drive wheels and other parts have high processing accuracy, the dimensional accuracy can reach ±0.01mm, and the matching clearance is controlled between 0.02-0.05mm. This high-precision lock core design can effectively improve the anti-technical opening performance of the lock, and the anti-technical opening time can reach more than 30 minutes. The key management function of the lock core is powerful, which can realize the customization of functions such as master key, master key, and same key to meet the personalized needs of different users in key management. For example, in hotels or corporate offices, through the customized key management system, it is convenient to hierarchically manage door locks in different areas, authorize the access rights of specific personnel, and improve the safety and management efficiency of door locks.

The lock body has a solid structure

The lock body adopts an integrated die-casting molding process, and the structure is solid and stable. Its internal parts are made of high-strength steel, and after fine processing and assembly, the strength and durability of the lock body are ensured. The lock tongue of the lock body can extend more than 25mm, and the lock tongue is strong and can withstand lateral pressure of more than 1000N without deformation or falling off. When the door is closed, the lock tongue and the door frame fit tightly, with a gap of less than 1mm, which effectively prevents illegal intrusion by external forces such as prying the lock tongue, providing reliable security protection for the door lock.

Convenient installation method

A variety of installation methods are provided, which can be selected according to different door structures and user needs. Common installation methods include open installation and concealed installation. The open installation method is suitable for most ordinary door bodies. The installation process is simple and quick. You only need to drill holes in the door body and fix the relevant accessories to complete the installation. Taking a standard indoor wooden door as an example, experienced installers can usually complete a set of knurled lever door handles in 15 to 20 minutes. Compared with some complex traditional door lock installation methods, the installation efficiency is improved by about 30% - 40%. The concealed installation method is suitable for places with high requirements for aesthetics. By pre-embedding the installation parts in the door body, the door handle and the lock body are concealed, making the door body surface neater and more beautiful. Regardless of the installation method, all installation accessories are precision-processed and well-matched in size to ensure a smooth installation process. The installed door handle can be opened and closed normally without jamming or loosening.

Good silent performance

The silent performance is fully considered during the design and manufacturing process. The parts inside the door handle and the lock body are precisely matched, and high-quality lubricating materials are used. During the opening and closing of the door, the friction and collision sounds between the components are extremely small, and the noise level can be controlled below 30 decibels, which will hardly cause noise interference to the surrounding environment. This silent design is particularly suitable for places with high requirements for quiet environment, such as bedrooms, hospitals, and libraries, providing users with a more comfortable and quiet use experience.

Knurled Lever Door Handles Application:

Residential security

Knurled lever door handles are widely used in the residential field and are suitable for various door types such as entrance doors and indoor room doors. Its exquisite surface treatment technology and diverse design styles can match various home decoration styles and enhance the overall aesthetics of the house. In terms of security performance, the high-quality lock cylinder and lock body design can effectively protect family property and personal safety. According to statistics, in the homes where the door handles have been installed, the incidence of theft cases caused by illegal opening of door locks has decreased by about 60%, providing reliable security protection for residents.

Commercial places

In commercial places such as office buildings, shopping malls, hotels, etc., knurled lever door handles are an ideal choice for door lock systems. Its durable material and sturdy structure can withstand the pressure of high-frequency use and personnel flow. For example, in large shopping malls, thousands of people enter and exit every day, and the door handles need to be opened and closed frequently. After one year of use, the door handles made of SS316 stainless steel can still maintain good performance and appearance without obvious wear or damage. At the same time, its key management system function has also been fully applied in commercial places, which is convenient for hierarchical management of door locks in different areas, improving the safety and management efficiency of commercial places.

Public facilities

This door handle also has important applications in the field of public facilities, such as schools, hospitals, libraries, etc. In these places, door handles not only need to have good durability and safety, but also need to be ergonomically designed to facilitate the use of people of different ages and physical conditions. For example, installing a door handle with a knurled design on the classroom door of a school can facilitate students to quickly open and close the door lock. At the same time, the knurled design increases friction and reduces the safety hazards caused by slippery hands. In the hospital environment, the antibacterial performance of door handles has also received attention. Door handles made of antibacterial stainless steel can effectively reduce the spread of bacteria and viruses and ensure the health and safety of patients.

Industrial buildings

In industrial buildings, such as factories, warehouses, laboratories, etc., the durability and safety of door locks are extremely high. Knurled lever door handles are made of high-quality stainless steel and a sturdy lock body structure, which can adapt to the harsh conditions in industrial environments, such as high temperature, humidity, corrosive gases, etc. For example, the door handle is installed on the workshop door of a chemical plant. After long-term exposure to an environment containing chemical substances, it can still maintain good performance without obvious corrosion or damage. At the same time, the high security performance of its lock core can effectively prevent unauthorized personnel from entering important areas, ensuring the safety and normal operation of industrial production.

Special uses

The door handle can also be used in some special-purpose places, such as museums, archives, vaults, etc. In these places, the security and reliability of door locks are extremely high, and door handles need to be combined with other security systems to form a multi-layer protection system. For example, knurled lever door handles are installed on the doors of the museum's cultural relics exhibition cabinets. Through linkage with electronic monitoring systems, alarm systems, etc., the status of the door locks can be monitored in real time. Once an abnormal opening occurs, the alarm device is immediately triggered to effectively ensure the safety of cultural relics. In archives, its good silent performance also helps to maintain a quiet reading environment.

Vehicles and ships

In addition to the common construction field, knurled lever door handles also have certain applications in vehicles and ships. Installing this door handle on the cab doors of some high-end engineering vehicles and special vehicles can provide good safety protection and user experience. Similarly, on the ship's cabin door, its corrosion resistance and waterproof performance are fully utilized, and it can adapt to the high humidity and salt spray corrosion conditions in the marine environment to ensure the safety and normal closure of the ship's cabin.

Knurled Lever Door Handles Maintenance:

Regular cleaning

Clean knurled lever door handles at least once a week. Use a soft damp cloth with a small amount of neutral detergent to gently wipe the surface of the door handle, lock cylinder and lock body to remove dust, stains and other attachments. Then wipe the surface with a clean dry cloth to avoid water residue that may cause water stains or corrosion on the stainless steel surface. During the cleaning process, be careful not to use a rough brush or abrasive cleaners to avoid scratching the knurled texture and plating on the surface. Regular cleaning can maintain the beauty and gloss of the door handle and extend its service life.

Proper lubrication

Properly lubricate the mechanical parts inside the lock cylinder and lock body once a quarter. Use a special lock lubricant, drip an appropriate amount of lubricant into the keyway of the lock cylinder and the rotating part of the lock body, and then insert and turn the key several times to evenly apply the lubricant to the surface of each mechanical part. The lubricant can form a protective film between the parts, reduce the friction coefficient, and reduce the degree of wear. After testing, the wear rate of the lock cylinder and lock body that are lubricated regularly can be reduced by about 40%, effectively extending the service life of the door lock and ensuring smooth opening and closing of the door.

Moisture-proof and rust-proof

Since the door handles and lock bodies are mostly made of stainless steel, although they have certain corrosion resistance, they still need to be moisture-proof and rust-proof in humid environments. In the rainy season or in a humid environment, a thin layer of anti-rust oil can be applied to the surface of the door handle and lock body to isolate moisture and air. At the same time, avoid long-term contact of the door handle with corrosive substances such as seawater and acid and alkali solutions. If the door handle is accidentally contaminated by corrosive substances, it should be immediately rinsed with plenty of clean water and wiped dry with a dry cloth. After taking effective moisture-proof and rust-proof measures, the rust rate of the door handle can be reduced by more than 90%, ensuring its normal use in harsh environments.

Avoid external force impact

During use, avoid applying excessive external force impact to the door handle. For example, do not pull or hit the door handle too hard to avoid deformation of the handle, damage to the lock tongue, or dislocation of internal parts of the lock body. If the door handle is loose or damaged, it should be repaired or replaced in time. According to statistics, door handle damage caused by external force impact accounts for about 30% of the total damage rate. By avoiding external force impact, the risk of door handle damage can be significantly reduced and its service life can be extended.

Check the lock cylinder and lock tongue

Check the matching of the lock cylinder and lock tongue once a month. Check whether the lock cylinder can rotate smoothly, whether the key is inserted and removed smoothly, and whether the lock tongue is flexible in extending and retracting. If it is found that the lock cylinder does not rotate smoothly or the lock tongue is not flexible, it can be cleaned and lubricated first. If there is still a problem, it is necessary to check whether the parts inside the lock cylinder and the lock body are damaged or worn, and repair or replace them in time. Through regular inspections, potential problems can be discovered and solved in time to ensure the safety and reliability of the door lock.

Store keys properly

Keep the door lock keys properly to avoid key loss or damage. If you need to copy the key, you should choose a professional lock shop or manufacturer to copy it to ensure the quality and accuracy of the key. Using a damaged key may scratch the keyway of the lock cylinder and affect the normal use of the lock. At the same time, avoid placing the key together with other hard objects to prevent the key surface from being scratched or damaged, which will reduce the service life of the key. Proper storage of keys can effectively avoid difficulties in opening the door lock due to key problems and improve the convenience and safety of door lock use.

Knurled Lever Door Handles FAQs:

What materials are used in the Knurled Lever Door Handles?

The Knurled Lever Door Handles are made from high-quality stainless steel, ensuring durability, corrosion resistance, and long-term reliability in various environments.

Are the Knurled Lever Door Handles texture comfortable to grip?

Yes, the Knurled Lever Door Handles are designed to provide a non-slip, comfortable grip while also adding a modern touch to the handle’s aesthetic.

What types of doors are compatible with these Knurled Lever Door Handles?

The Knurled Lever Door Handles can be installed on various doors, including entry doors, bedroom doors, and other interior doors, making it a versatile choice for both residential and commercial spaces.

Can the Knurled Lever Door Handles be customized?

Yes, the Knurled Lever Door Handles can be customized in terms of finishes or other features based on bulk order requests to meet specific design or functional requirements.

Do the Knurled Lever Door Handles require regular maintenance?

The Knurled Lever Door Handles require minimal maintenance. Occasional cleaning with a damp cloth will maintain its satin brushed and mirror-polished finish.