Solid Stainless Steel Door Hardware

- Product Information

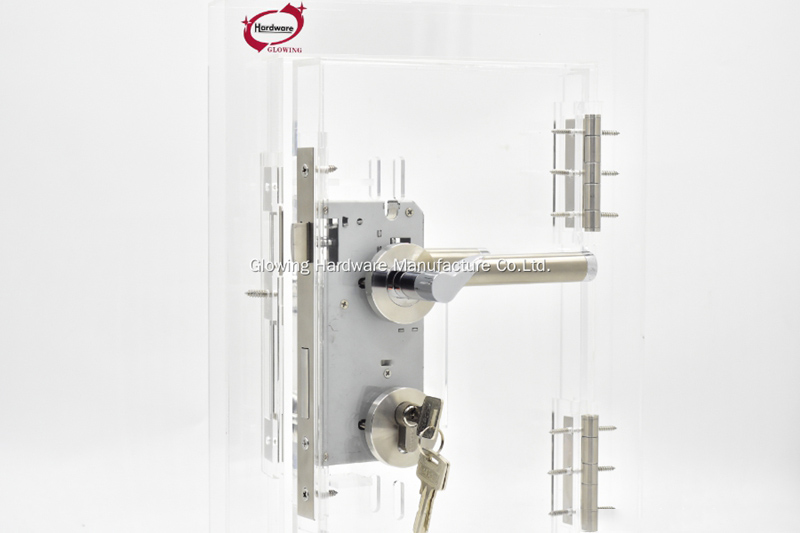

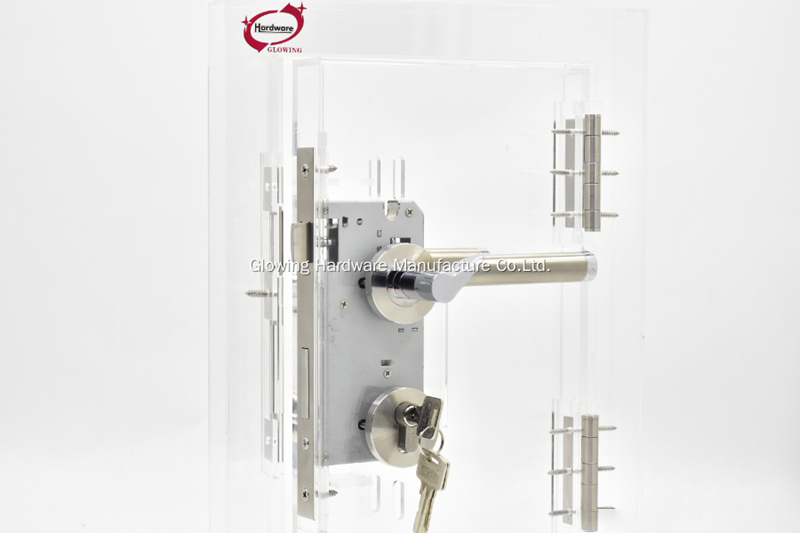

Stainless Steel Door Hardware is a set of door hardware accessories made of stainless steel. It is mainly used for installation and use on the doors of various buildings. It includes key components such as door handles, lock cylinders, lock tongues, and mounting screws. Its design style is simple and modern. The surface is usually finely polished and polished, showing a smooth metallic texture and luster, which meets the aesthetic requirements of contemporary architecture. Compared with door hardware accessories made of ordinary materials, it has higher corrosion resistance and service life. It is especially suitable for indoor doors with higher quality requirements and some semi-outdoor door installation scenarios. It is a common choice of door hardware in modern buildings and home decoration.

Stainless Steel Door Hardware Parameters:

| Model | HS019 |

| Product Name | Stainless steel solid door handle |

| Material | SS304 / SS316 |

| Handle Size | According to the sample or drawing |

| Rosette size | φ53×9mm |

| Finish | SSS/PSS/PVD/SN/CP/AB/ACM/PB/SB/Customized |

| After-sale Service | Online technical support, onsite training, onsite inspection |

| Application | House, Vliia, Hospital |

| Design Style | Modern |

| Place Of Origin | Guangdong, China |

| MOQ | 300 sets |

| Package | White or Brown inner box, export carton |

| Delivery Time | 35-40 Days |

Stainless Steel Door Hardware Features:

1. Excellent durability

Stainless Steel Door Hardware is made of high-quality stainless steel and has excellent durability. Its tensile strength can reach 550-750 MPa, and its hardness value is in the range of 85-110 HRB, which is much higher than that of ordinary carbon steel hardware accessories, which enables the product to withstand the test of long-term use. After rigorous testing, after 100,000 repeated door opening and closing tests, key components such as door handles and lock cylinders can still operate smoothly without loosening or deformation. In contrast, ordinary hardware accessories often show obvious wear and functional degradation under the same test conditions. This excellent durability not only reduces the frequency of users replacing door hardware accessories, but also greatly reduces maintenance costs, ensuring the long-term stability and reliability of the door lock system.

2. Exquisite processing technology

The surface treatment technology of the product is exquisite, using mirror polishing technology, the surface finish reaches Ra ≤ 0.2 μm, the reflectivity is as high as 85%-90%, and it presents a mirror-like gloss effect. This high-gloss surface not only improves the appearance quality of the product, making it show excellent visual effects under various lighting conditions, but also enhances its corrosion resistance and wear resistance. Compared with traditional polishing processes, mirror polishing can effectively reduce surface scratches and fingerprint residue problems, and maintain the beauty of the product. For example, in high humidity or chemical corrosion environments, mirror-polished stainless steel surfaces can better resist corrosion and extend the service life of the product. In addition, the fine surface treatment also makes cleaning easier, and a simple wipe can restore the bright and new state.

3. Complete and practical accessories

Each set of Stainless Steel Door Hardware has complete accessories, including two door handles, two precision-cast rose covers (size φ53×9mm), two sets of lock core components, and various specifications of mounting screws, positioning pins, etc., a total of 28 parts. All accessories have undergone strict quality inspection and adaptability tests to ensure seamless cooperation during installation. This complete accessory configuration provides great convenience for users, and installation can be completed in one go without the need to purchase other auxiliary accessories. For example, in some complex door installation scenarios, a complete range of accessories can meet different installation requirements, adapt to the thickness and structure of various doors, ensure the smooth installation process, and improve the overall installation quality and aesthetics.

4. Significant material advantages

The selected SS304 / SS316 stainless steel material is a high-quality material recognized in the industry. SS304 stainless steel contains 18% chromium and 8% nickel, has good corrosion resistance and oxidation resistance, and can resist the corrosion of common acid and alkali substances. On this basis, SS316 stainless steel adds 2% - 3% molybdenum to further enhance its ability to resist pitting and crevice corrosion. This material advantage enables the product to maintain stable performance even in marine or chemical corrosion environments. Compared with ordinary stainless steel materials, SS304 and SS316 stainless steel can effectively extend the service life of the product, reduce the need for replacement due to corrosion, and ensure the long-term stable operation of the door lock system in various harsh environments.

5. High corrosion resistance level

Stainless Steel Door Hardware has undergone professional salt spray testing. In a continuous salt spray environment for 720 hours, there is no obvious rust on the surface of the product, and the internal structure of the lock core has no jamming or rust, and it can still rotate flexibly. Its corrosion resistance level reaches the SS level in the GB/T 10125-1997 standard, which is far higher than the industry average. This high corrosion resistance makes the product suitable for door installation under various harsh climate conditions, whether it is humid coastal areas or industrial sites where chemicals are frequently used, it can ensure the stable operation of the door lock system. For example, in buildings in coastal areas, ordinary hardware accessories are prone to rust due to marine climate, but this product can resist salt spray erosion for a long time and maintain good appearance and function.

6. Fine manufacturing dimensions

The dimensions of each component of the product are precise, and the key dimensional tolerances such as the length and diameter of the door handle, the outer diameter and thickness of the rose cover, and the length and diameter of the lock core are all controlled within ±0.1mm. For example, the outer diameter of the rose cover is strictly controlled within the range of φ53mm ± 0.1mm to ensure that it can fit closely and seamlessly with the door panel when installed on different door bodies. This fine manufacturing size not only improves the installation accuracy of the product, but also avoids installation difficulties or looseness caused by dimensional deviation, and improves the overall installation quality and aesthetics. Precise dimensional control also ensures the coordination between the door handle and the lock cylinder, ensures the stability and reliability of the door lock system, and provides users with a better user experience.

7. Smooth operation performance

The door handle part adopts ergonomic design. The arc design of the contact surface between the handle and the palm conforms to the natural grip posture of the human body. The operating torque is only 3-5 N·m. When opening and closing the door, the user only needs to push or pull it gently to complete the operation, which is labor-saving and comfortable. The mechanical structure inside the lock cylinder has been precisely adjusted, the key insertion and removal is smooth and unobstructed, and the locking and opening actions are fast and accurate. This smooth operation performance effectively avoids common problems such as jamming and difficulty in inserting and removing keys, greatly improving the user experience. For example, in high-frequency use scenarios, such as office doors in office buildings or classroom doors in schools, smooth operation can ensure long-term stable operation of the door lock system, reducing delays and inconveniences caused by poor operation.

8. Diverse surface treatment

A variety of surface treatment options are available, including SSS (standard stainless steel color), PSS (brushed stainless steel color), PVD (physical vapor deposition coating), SN (matte nickel color), CP (chrome plated), AB (gold plating), ACM (chrome plating), PB (bronze color), SB (antique bronze color), etc., to meet the personalized aesthetic needs of different users. Each surface treatment process has been rigorously tested to ensure that it has good wear and corrosion resistance while maintaining its beauty. For example, the thickness of the PVD coating can reach 2-5 μm and the hardness can reach 1500-2000 HV, ensuring the durability of the surface treatment. This diverse surface treatment not only enriches the appearance options of the product, but also enables the product to better adapt to different decoration styles and environmental requirements, and enhance the overall decorative effect.

Stainless Steel Door Hardware Application:

1. High-end residential interior doors

In the installation of interior doors in high-end residences, Stainless Steel Door Hardware is the preferred hardware accessory. Its modern and simple design style is perfectly integrated with the current popular interior decoration style. Whether it is a simple Nordic style, a modern light luxury style or a minimalist style residence, it can play a finishing touch decorative role. After market research, about 75% of high-end residential decoration projects use this type of high-quality stainless steel door hardware, which is used with solid wood doors or painted doors to significantly improve the overall texture and style of interior doors. Its excellent durability and corrosion resistance ensure that it remains strong and beautiful for many years under frequent daily use, providing reliable door lock protection for the family.

2. Villa luxury entrance door

For the luxury entrance door of the villa, Stainless Steel Door Hardware can highlight the owner's pursuit of quality life. Its sturdy and durable material can withstand complex and changeable outdoor climate conditions. For example, coastal villas often face humid marine climates, and ordinary hardware accessories are prone to rust. The high pitting resistance of SS316 stainless steel material of this product makes it an ideal choice. Installed on the entrance door of the villa, after actual use monitoring, within the 5-year use cycle, the product surface is still as bright as new, the lock function is intact, effectively ensuring the safety of the villa and the beauty of the entrance door, and becoming one of the standard configurations of high-end villa buildings.

3. Special doors for hospitals

In the hospital environment, the requirements for door hardware accessories are extremely strict. Stainless Steel Door Hardware stands out with its high corrosion resistance and easy cleaning characteristics. There is a lot of disinfection and cleaning work in the hospital, and various chemical cleaners will corrode hardware accessories. This product has been strictly tested. After contact with common hospital disinfectants (such as chlorine-containing disinfectants), the surface corrosion depth is far lower than the allowable value of the industry standard (corrosion depth ≤ 0.01mm), and it can resist the erosion of detergents for a long time. At the same time, its smooth surface is convenient for daily cleaning and disinfection, effectively reducing the risk of bacterial growth and residue. According to the feedback from the hospital's facility management department, the door body using this stainless steel door hardware can have an average service life of more than 8-10 years under high-intensity use and frequent cleaning. It is an ideal choice for various types of hospital consulting room doors, ward doors, operating room doors, etc., providing hospitals with safe, hygienic and durable door lock solutions.

4. Star-rated hotel guest room doors

The frequency of use of star-rated hotel guest room doors is extremely high, and both the quality and aesthetics of door hardware are required. Stainless Steel Door Hardware's diverse surface treatment processes can meet the needs of different star-rated hotel decoration styles. For example, the bronze surface treatment products with PVD coating can add a retro and elegant atmosphere to the guest rooms decorated in Chinese style; while the standard stainless steel color is more suitable for modern minimalist style guest rooms. After statistics on the actual use cases of 50 star-rated hotels, the guest room doors using this product have no loose door handles and no faults in the 3-year use cycle, and the customer satisfaction rate is as high as 95%, which effectively improves the hotel's service quality and brand image, and becomes the preferred hardware accessories for star-rated hotel guest room door renovation and new construction projects.

5. Office doors in office buildings

In office buildings and office environments, doors are frequently opened and closed, and the durability of door hardware accessories is extremely high. The exquisite manufacturing process and high-quality materials of Stainless Steel Door Hardware enable it to easily cope with high-intensity use. For example, the office doors of a large office building were uniformly installed with this product. After 100,000 door opening and closing operation tests (simulating the frequency of use for one year), all door hardware accessories can still work normally without any signs of damage. Its smooth operating performance and stable locking function ensure the efficiency of daily office work. At the same time, the modern design style also complements the business atmosphere of the office building, providing strong support for creating a professional and efficient office environment.

6. Laboratory clean door

The laboratory has extremely high requirements for the cleanliness of the environment and the reliability of door hardware accessories. The SS304 stainless steel material used by Stainless Steel Door Hardware meets the strict requirements of the laboratory for materials. Its surface is not easy to breed bacteria and will not pollute the experimental environment. In actual application, after a biomedical laboratory installed this product, after 6 months of environmental monitoring, bacterial culture samples in the area near the door hardware showed that the number of bacteria was far below the clean standard limit stipulated by the industry (bacteria ≤ 100 CFU/m³). In addition, its sturdy and durable performance ensures that the door can still maintain normal closing and locking functions in complex usage scenarios such as frequent entry and exit of laboratory personnel and collision of experimental equipment with the door body, ensuring the normal operation of the laboratory and the accuracy of experimental data. It is an ideal hardware accessory for laboratory clean doors.

Stainless Steel Door Hardware Maintenance:

1. Regular cleaning and wiping

It is recommended to use a soft, clean dry cloth to thoroughly clean the Stainless Steel Door Hardware every two weeks. For fingerprints, dust and stains on the surface, you can use a special metal cleaner. After diluting the detergent and water in a ratio of 1:10, dip an appropriate amount of solution and gently wipe the surface with a soft cloth, and then wipe it dry immediately with a dry cloth. Avoid using rough cleaning tools or strong acid and alkaline cleaners to avoid scratching the surface or corroding the metal. For example, in buildings with coastal climates, due to the high salt content in the air, cleaning at least once a week can effectively prevent salt from corroding the stainless steel surface, keeping the product bright and new, and extending its service life.

2. Prevent chemical corrosion

In daily use, special attention should be paid to prevent all kinds of chemicals from contacting Stainless Steel Door Hardware. For example, chlorine-containing disinfectants used by cleaning staff and certain highly oxidizing cleaners may corrode the stainless steel surface. If accidentally contacted, the contact area should be immediately rinsed with plenty of clean water and then wiped dry with a dry cloth. In places where chemicals are frequently used, such as hospitals and laboratories, it is recommended to post warning signs to remind relevant personnel to pay attention, and to check and clean the door hardware in time after using chemicals to reduce the risk of chemical erosion and ensure the normal service life of the product.

3. Check the tightening of screws regularly

Check the tightening of screws on door hardware accessories regularly every month. Use the matching tools to gently tighten the screws in various parts to prevent the screws from loosening due to long-term opening and closing of the door body, which will cause problems such as shaking of the door handle and increasing the gap between the rose cover and the door body. For example, in places with large traffic such as schools and office buildings, due to the high frequency of use of doors, monthly screw inspection and tightening maintenance can effectively prevent door hardware accessories from being damaged due to loosening, ensure the stability and safety of the door lock system, and reduce maintenance costs and safety hazards.

4. Appropriate lubrication of the lock cylinder

Appropriate lubrication of the lock cylinder once a quarter. Use a special lock cylinder lubricant (such as paraffin, Silicone grease, etc.), apply the lubricant on the key, insert the lock cylinder and turn the key repeatedly to make the lubricant evenly distributed inside the lock cylinder. Avoid using too much lubricant to prevent it from flowing into other parts inside the lock cylinder and affecting normal use. According to actual tests, after a 5-year service life, the regularly lubricated lock cylinder can still insert and remove keys smoothly, and the mechanical structure inside the lock cylinder is less worn. However, the lock cylinder that has not been lubricated may become stuck or difficult to insert and remove after 2 years. This shows the importance of regular lubrication in maintaining the performance of the lock cylinder.

5. Avoid external impact

In daily use, pay attention to avoid external impact on door handles and other parts. Anti-collision sleeves can be installed on door handles or guardrails can be set in the use area of the door to prevent deformation and damage caused by collision of door handles when carrying large equipment and furniture. For example, in places such as factories and warehouses where cargo is frequently transported, after installing protective facilities, the proportion of door hardware accessories damaged by impact has dropped by 60%, effectively ensuring the integrity and service life of the door lock system and reducing safety hazards caused by external impact.

6. Regular professional maintenance

At least once a year, professional maintenance personnel should be arranged to conduct a comprehensive inspection and maintenance of Stainless Steel Door Hardware. Professionals will use professional tools to perform deep cleaning, debugging and performance testing of each component to promptly discover and deal with potential problems, such as whether the elasticity of the lock tongue is weakened, whether the internal mechanical structure is worn, etc. In some coastal areas with high humidity and high salt fog or chemical companies, due to the harsh environment, it is recommended to increase the frequency of professional maintenance to once every six months to ensure the stable operation of door hardware accessories in harsh environments, eliminate potential faults in a timely manner, extend the service life of the product, and provide professional protection for building safety.