Stainless Steel Door Lever Handles

- Product Information

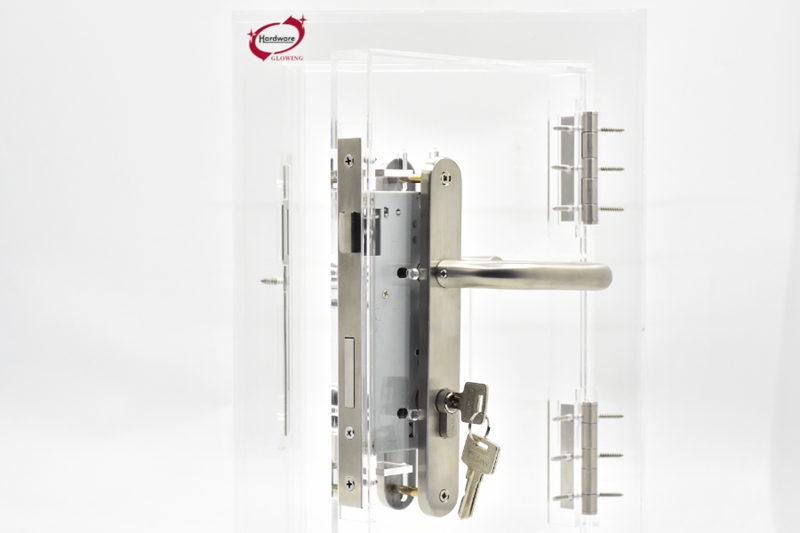

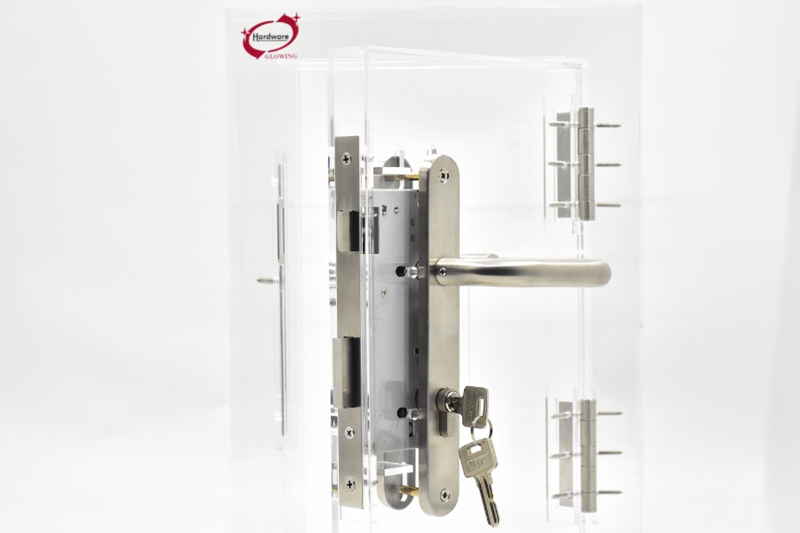

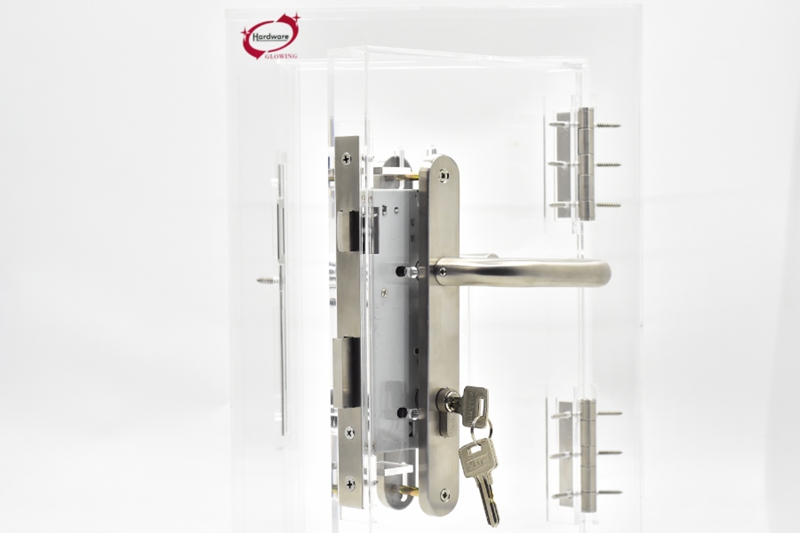

Stainless Steel Door Lever Handles are access control components made from high-quality metal, primarily used for door opening and closing. Through precision machining and ergonomic design, they provide users with stable and reliable operation, ensuring a smooth triggering mechanism even after prolonged use. Their refined surface treatment and smooth touch eliminate the harsh, cold metal feel. They are also adaptable to various climates, with no impact on performance due to temperature fluctuations.

Stainless Steel door lever handles Parameters:

| Model | PL007 |

| Product Name | Stainless steel door lever handle |

| Material | SS201/SS304/SS316 |

| Handle Size: | Customized |

| Plate Size | 240×30×8mm |

| Finish | SSS/PSS/PVD/SN/CP/AB/ACM/PB/SB/Customized |

| After-Sale Service | Online technical support, Onsite Training, Onsite Inspection |

| Application | House, school, hotel room, hospital, office building |

| Design Style | Modern |

| Place Of Origin | Guangdong, China |

| MOQ | 200 SETS |

| Brand Name | Glowing Hardware |

| Package | White or Brown inner box, export carton |

| Delivery Time | 30-35 days |

Stainless Steel Door lever handles Features:

High-Strength Material Construction

Stainless Steel Door Lever Handles are made of SS201, SS304, or SS316 stainless steel, each of which offers exceptional durability. The SS316 model boasts a nickel content of 10% and a chromium content of 16%, resulting in a tensile strength test result of 520 MPa to 670 MPa, significantly exceeding the standard for standard building hardware.

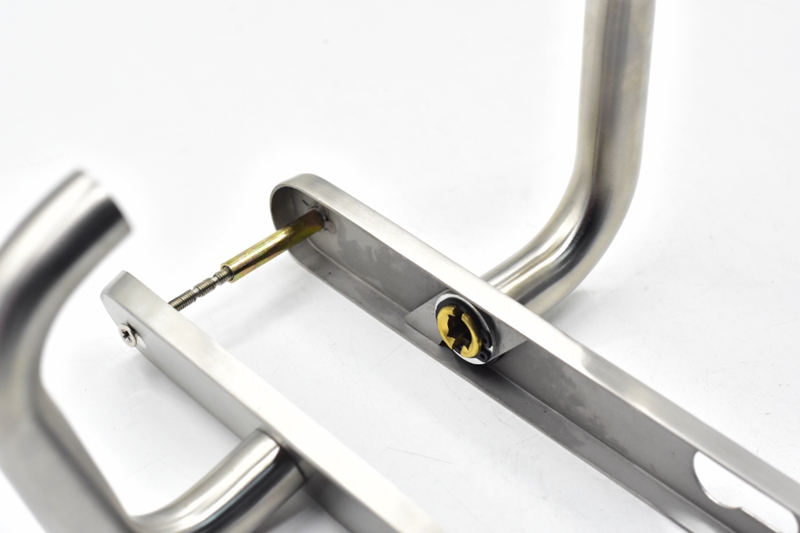

Precision Lever Structure Design

The lever is constructed using cold-formed seamless tubing with a wall thickness of 1.5 mm. Internal ribs enhance the torsional strength to 120 N·m. Cyclic testing has shown that the lever exhibits less than 0.2 mm deformation after 100,000 cycles of repeated force, fully meeting international standards for building hardware durability.

Customizable Sizes

The handle base measures 240 × 30 × 8 mm and can be customized to meet door thickness and customer requirements, with a length tolerance within ±0.15 mm. The lever's curvature is optimized based on a human hand database, with a grip area measuring 38mm wide and 22mm deep, ensuring even force distribution.

Multiple Surface Treatments

Surface treatments include SSS (mechanical polishing), PSS (electrochemical polishing), and PVD (physical vapor deposition). The PVD coating thickness ranges from 0.8 to 2 microns, with a surface roughness Ra of ≤0.4 microns. Scratch testing shows that the PVD coating's adhesion meets HF1 standards, with a wear resistance exceeding 2,000 steel wire abrasions without exposing the base.

Optimized Rust Resistance

The material undergoes a passivation treatment to form a chromium-rich oxide layer. X-ray photoelectron spectroscopy analysis shows a surface chromium/iron ratio exceeding 1.5, significantly improving pitting corrosion resistance. Accelerated aging tests show no signs of corrosion after 240 hours in an environment with 95% humidity and 38°C.

Optimized Mounting Structure

The mounting base features a pre-buried reinforced design, with mounting hole positioning tolerances controlled to ±0.1mm. The supporting fasteners meet the 4.8 tensile strength standard. Tests show that in the vibration environment generated by frequent opening and closing of the door, the bolt preload loss rate of the installation structure is less than 15% after 50,000 cycles of testing, which is significantly higher than the industry average.

Stainless Steel Door Lever Handles Application:

Hotel Rooms

In hotel applications, these stainless steel door lever handles, with their corrosion resistance and durability under frequent use, are particularly well-suited for the daily operation of guest room doors. Actual operational data shows that in hotels with an 85% occupancy rate, the handles can last for over eight years without replacement, and their surface treatment resists chemical corrosion from cleaning agents. Their silent design keeps opening and closing noise levels below 35 decibels, enhancing the guest experience.

Medical Facilities

In hospital environments, antimicrobial and easy-to-clean handles are crucial. The SS316 material undergoes a special surface treatment that reduces bacterial adhesion by 70%, and can be repeatedly wiped with medical-grade disinfectants. Statistics show that even with routine disinfection six times daily in intensive care units, the handles show no corrosion or discoloration.

Educational Facilities

School classroom and dormitory doors are subject to frequent use, and this handle lever structure has been tested to withstand over 200,000 operations. Its mounting structure is designed to withstand the impact of abnormal use, with actual tests showing it can withstand a radial load of 500 Newtons without permanent deformation, making it particularly suitable for crowded spaces.

Office Buildings

This handle, adopted in high-end office buildings, fully demonstrates its modern design and durability. Long-term monitoring shows that in an office area with a daily foot traffic of 2,000 people, the handle mechanism maintains its initial operating force after five years of operation, requiring no adjustment or maintenance. Its surface treatment effectively resists sweat corrosion, maintaining its visual quality.

Stainless Steel Door Lever Handles Maintenance:

Routine Cleaning and Maintenance

Wipe the surface monthly with a soft cloth dampened with a neutral pH detergent solution, then wipe clean with a dry cloth. Avoid using cleaners containing chloride ions or abrasives to prevent damage to the surface passivation film. After cleaning, inspect the mounting fasteners to ensure they are not loose.

Surface Protection

Apply a special stainless steel care agent to the surface every six months to form a protective layer. This agent contains corrosion inhibitors, which fill the surface pores and reduce the penetration of corrosive media. After treatment, allow the agent to cure for two hours. Avoid contact with liquids during this time.

Operating Mechanism Inspection

Inspect the lever mechanism quarterly to confirm that the shaft clearance is normal. Use a torque wrench to measure the operating torque. If the operating force is abnormally increased, contact a professional to adjust the internal spring mechanism.

Environmental Adaptability Maintenance

In high-temperature and high-humidity environments, reduce maintenance intervals, paying particular attention to the contact area between the base and the door body. It is recommended to check the preload of the mounting bolts every three months to prevent loosening due to thermal expansion and contraction of the material.

Maintenance During Long-Term Non-Use

If the door will be out of service for an extended period, apply a small amount of lubricant to the handle's movable area to prevent the shaft from binding. We recommend using lubricant that meets NLGI Grade 2 standards and has a dropping point of at least 180°C to prevent heat loss. Also, cover the entire handle with a dust cover to reduce dust accumulation.

Stainless Steel Door Lever Handles FAQs:

Is this stainless steel door handle truly rust-proof?

Yes, high-quality stainless steel door handles are extremely rust-resistant. The SS304 and SS316 stainless steel we use contain higher levels of nickel and molybdenum, making them highly resistant to corrosion. This rust resistance works by naturally forming a passivation film on the surface of the material. This film isolates oxygen and moisture, preventing further oxidation of the iron within. Therefore, as long as this protective film is not severely damaged or exposed to strong chemical agents for a long time, the handle will remain rust-free for a long time.

What are the surface finish options for the handle?

We offer a variety of finishes to meet different aesthetic and functional requirements. Key options include: Satin Finish (SSS), which creates a delicate, soft matte finish that effectively hides fingerprints and minor scratches; Mirror Polish (PSS), which offers a mirror-like finish that creates a modern, luxurious look and is easy to clean; and Physical Vapor Deposition (PVD), available in colors like champagne gold, black nickel, and antique bronze. The coating is extremely hard, wear-resistant, long-lasting, and offers excellent corrosion resistance.

Is installing this door handle complicated?

Installation is designed to be simple, typically requiring no welding. Our handles are mechanically mounted, secured with pre-drilled holes and bolts. All necessary mounting screws and a positioning template are included as standard. You only need common tools such as a screwdriver, a tape measure, and a power drill to pre-drill the holes.

How durable is this door lever handle?

This door lever handle is designed for high-use commercial and heavy-duty domestic environments, offering exceptional durability. Its core structure is precision-manufactured from high-quality stainless steel and typically incorporates a robust spring mechanism and bearing system to ensure smooth, reliable operation. Rigorously tested, these high-quality handles can withstand over 500,000 or even 1,000,000 cycles of repeated opening and closing without failure or noticeable degradation.

What if the handle becomes loose or erratic in the future?

Most minor issues can be resolved with simple maintenance. If you are unable to resolve the issue yourself, contact our customer service team immediately for professional technical assistance or a replacement part. Avoid forced disassembly, as this may cause further damage.