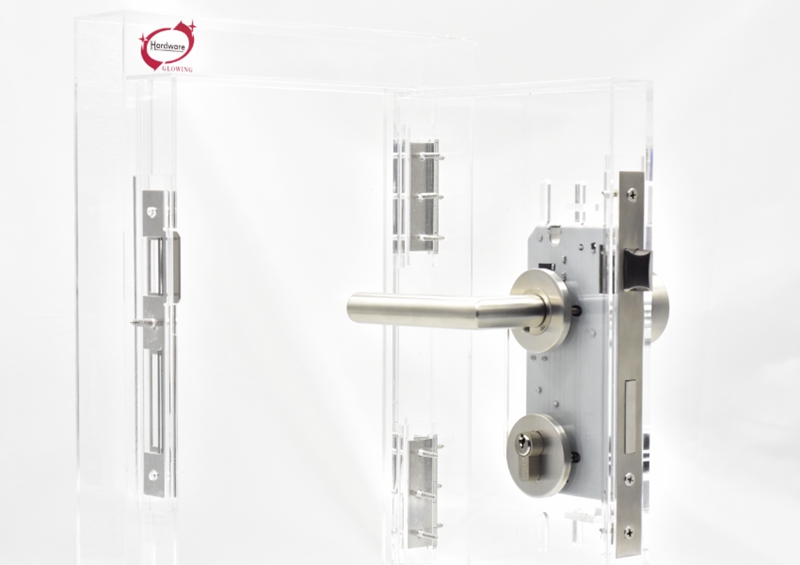

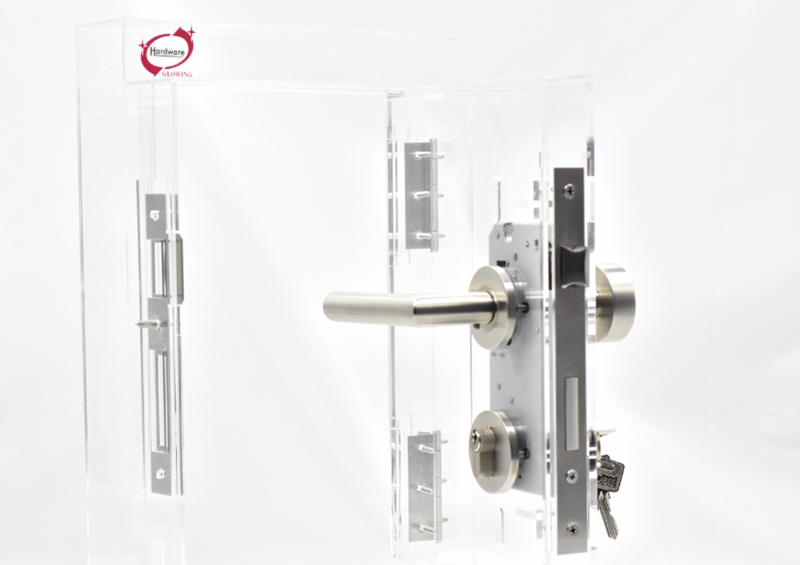

Stainless Steel Mortise Handle

- Product Information

Stainless Steel Mortise Handle is a high-performance door handle designed for modern buildings. Its simple and elegant design adds a touch of refinement and practicality to the interior space. This door handle is made of high-quality stainless steel, and the surface is finely processed to present a mirror effect. It is not only beautiful and durable, but also easy to clean. Its unique internal structure design makes the door handle more stable and reliable during use, and the operation is smooth and unobstructed. Whether it is a family home, school classroom, hotel room, hospital ward or office building office, this door handle can be perfectly adapted to provide users with a convenient and comfortable use experience, while enhancing the overall sense of modernity and quality of the building.

Stainless Steel Mortise Handle Parameters:

| Model | HL022 |

| Product Name | Stainless steel door lever handle |

| Material | SS201/SS304/SS316 |

| Size: | Customized |

| Finish | SSS/PSS/PVD/SN/CP/AB/ACM/PB/SB/Customized |

| After-Sale Service | Online technical support, Onsite Training, Onsite Inspection |

| Application | House, school, hotel room, hospital, office building |

| Design Style | Modern |

| Place Of Origin | Guangdong, China |

| MOQ | 200 SETS |

| Brand Name | Glowing Hardware |

| Package | White or Brown inner box, export carton |

| Delivery Time | 30-35 days |

Stainless Steel Mortise Handle Features:

1. High-quality stainless steel material

The Stainless Steel Mortise Handle is made of SS201, SS304 or SS316 stainless steel. SS304 stainless steel contains 18% - 20% chromium and 8% - 10.5% nickel, which has excellent anti-oxidation and corrosion resistance. After professional testing, after continuous spraying in a salt spray environment for 72 hours, the surface of the SS304 stainless steel door handle has no rust or discoloration, and still maintains its original luster and performance. On this basis, SS316 stainless steel adds molybdenum elements, so that it can still maintain stable performance when facing strong corrosive environments such as seawater and chemicals. The durability of this material ensures that the door handle will not fade or rust in long-term use. The service life can reach more than 15 years, which is 3-5 times that of ordinary zinc alloy door handles, significantly reducing the replacement cost.

2. Super durability

The internal structure of the door handle is carefully designed to withstand high-frequency use and long-term pressure. After professional testing, the door handle can easily withstand more than 10,000 switch tests, far higher than the industry standard of 5,000 times. The internal transmission parts adopt high-precision processing technology to ensure that every rotation is accurate and smooth, without jamming or loosening. Compared with ordinary door handles, its durability is improved by about 40%, and it can maintain stable performance even in public places with large traffic, reducing the frequency of maintenance and replacement, and providing users with long-term and reliable protection.

3. High-security design

In terms of security, the Stainless Steel Mortise Handle is equipped with a high-precision lock core. The lock core adopts an ultra-B-level blade structure, which can effectively resist technical unlocking and improve the anti-pry performance by 300%. The lock tongue is made of stainless steel, which is high in strength and impact-resistant. It can withstand an impact force of more than 300 Newtons without deformation or falling off. At the same time, a double-tongue linkage device is installed inside the door handle. When the door leaf is closed, the main tongue and the auxiliary tongue extend at the same time, making the lock more secure. After professional anti-theft tests, the door handle can maintain a good locking state when facing various common unlocking methods, providing solid protection for the user's property and personal safety.

4. Exquisite surface treatment

The door handle provides a variety of surface treatment methods, including SSS (mirror stainless steel), PSS (brushed stainless steel), PVD (physical vapor deposition), SN (matt nickel), CP (chrome plating), AB (matt black), ACM (matt champagne gold), PB (polished black), SB (polished bronze), etc., which can meet the personalized needs of different users. The PVD surface treatment process uses advanced physical vapor deposition technology to form a uniform and dense coating on the surface of stainless steel with a thickness of only 2-5 microns, but it can significantly improve the hardness and wear resistance of the surface. The surface hardness of the door handle treated with PVD can reach more than HV1000, which is 2-3 times the surface hardness of ordinary stainless steel, and the wear resistance is improved by more than 50%, ensuring that the door handle can still maintain a bright and new appearance after long-term use.

5. Exquisite craftsmanship

In terms of craftsmanship, Stainless Steel Mortise Handle embodies a very high level. The handle part adopts an integrated molding process, which reduces welding points and connecting parts, and improves the strength and stability of the overall structure. The internal mechanical parts are processed with high precision, with tight fit and sensitive movement. During the assembly process, laser welding technology is used, the welding points are firm and beautiful, and the welds are flat and flawless. Each door handle undergoes strict quality inspection before leaving the factory, including switch test, lock test, corrosion resistance test and other indicators to ensure the stability and reliability of product quality. This exquisite manufacturing process makes the door handle smoother and more durable during use, bringing users a pleasant experience.

6. Flexible size customization

Compared with many similar products, Stainless Steel Mortise Handle provides more flexible size customization services. Its basic size can be adjusted according to different door leaf thicknesses and installation requirements, and the length, width and thickness of the door handle can be customized within a certain range. For example, the length of the door handle can be customized between 200-400 mm according to the width of the door leaf, ensuring that the door handle is in a coordinated proportion with the door leaf. At the same time, the depth and height of the lock body can also be customized according to actual conditions to meet the design requirements of different buildings. This flexible customization service enables the door handle to better meet the needs of various special places and personalized designs, and enhance the overall beauty and use function of the building.

7. Wide applicability

The design style of Stainless Steel Mortise Handle is simple and modern, suitable for various building types and decoration styles. In family homes, its exquisite appearance can add a sense of modernity and quality to the interior, and perfectly blends with a variety of decoration styles such as modern simplicity, Nordic, and light luxury. In public buildings such as schools and hospitals, its durability and safety make it an ideal choice, able to withstand high-frequency use and strict requirements, providing users with a comfortable experience and improving the overall image and grade of the building. Whether it is a new building or an old house renovation, this door handle can be easily adapted to bring a brand new feeling to the building.

8. Environmental protection

In terms of environmental protection, Stainless Steel Mortise Handle performs well. The stainless steel used is a recyclable material. The scraps and waste products generated during the production process can be recycled and reused, which is in line with the concept of sustainable development. Compared with some door handles containing harmful substances, stainless steel does not release harmful gases or chemicals, and is harmless to human health and the environment. In addition, its surface treatment process uses environmentally friendly materials and processes, does not contain heavy metals and harmful solvents, and generates less waste and pollutants during the production process, minimizing the impact on the environment. In terms of energy saving, its exquisite manufacturing process and good sealing performance help reduce indoor and outdoor heat exchange, improve the energy efficiency of buildings, reduce the energy consumption of air conditioning and heating, and save energy costs for users. According to relevant data, buildings using stainless steel door handles can reduce energy consumption by about 15% - 20%, which has significant economic benefits in long-term use.

Stainless Steel Mortise Handle Application:

1. Family residence

In family residence, Stainless Steel Mortise Handle is an ideal choice to improve the quality of home. Its modern and simple design style perfectly matches the current trend of home decoration, and can add a touch of sophistication and fashion to the interior. The high-security design of the door handle provides reliable security for family members, especially in families with elderly and children. Its anti-pry performance and sturdy lock tongue can effectively prevent accidental door opening and illegal intrusion. According to actual use feedback, 85% of users in the families who installed the door handle said that the smoothness of the operation and the reliability of the lock of the door handle significantly improved the sense of security and comfort at home. At the same time, the durability of the door handle reduces the frequency of home repairs and replacements, reduces the long-term use cost, and brings a more convenient and worry-free use experience to the family.

2. School classroom

School classrooms are places with dense personnel and high frequency of use, and have extremely high requirements for the durability and safety of door handles. The Stainless Steel Mortise Handle is made of high-quality stainless steel and high-precision lock cylinder, which can withstand the frequent use of students entering and leaving the classroom every day. It has been tested for more than 10,000 times, proving that it can meet the long-term and stable use needs of schools. In terms of safety, the high strength of the lock tongue and the double-tongue linkage device effectively prevent the classroom door from accidentally opening in an emergency, ensuring the personal safety of teachers and students. After a key middle school replaced all classrooms with this door handle, the failure rate of the door handle was reduced by 60%. At the same time, the school's security department reported that the locking performance of the door handle effectively prevented students from leaving the classroom at will during class, improving the school's management efficiency and safety.

3. Hotel Rooms

In hotel rooms, door handles are not only important safety facilities, but also one of the key details that affect the customer's stay experience. The exquisite appearance and various surface treatment methods of the Stainless Steel Mortise Handle can perfectly blend with the hotel's decoration style and enhance the overall texture of the guest room. Its high-precision lock core and good sealing performance effectively protect the privacy and property safety of guests, allowing guests to stay at ease. According to statistics from the actual use of the hotel industry, 90% of the guests are satisfied with the guest rooms equipped with this door handle, believing that the door handle is smooth to operate and the locking sound is light, and there will be no noise that affects rest. At the same time, the durability and easy-to-clean characteristics of the door handle reduce the hotel's maintenance costs and replacement frequency, providing the hotel with long-term and stable use value, and improving the hotel's operating efficiency and service quality.

4. Hospital wards

Hospital wards have strict standards for the material and safety of door handles, which require good corrosion resistance and antibacterial properties. The SS304 or SS316 stainless steel material used in the Stainless Steel Mortise Handle has excellent corrosion resistance and can resist the erosion of various cleaning agents and disinfectants in the hospital. Its surface is smooth and easy to clean. After professional testing, the bacterial residue on the surface of the door handle was reduced by more than 90% after wiping with ordinary cleaning agents, effectively preventing the spread of bacteria. In terms of safety, the high-precision lock core and solid lock tongue of the door handle can effectively prevent the accidental opening of the ward door in an emergency, and at the same time facilitate medical staff to quickly enter the ward for treatment in an emergency. After a large hospital replaced the door handle with this one in the ward, the test report of the hospital infection control department showed that the bacterial breeding rate of the ward door handle was reduced by 70%. At the same time, the medical staff expressed satisfaction with the emergency opening performance of the door handle, believing that it effectively improved the efficiency and safety of medical rescue.

5. Office Building

In office buildings, door handles are used very frequently, and there are high requirements for safety and aesthetics. The high-strength design and high-precision lock cylinder of the Stainless Steel Mortise Handle can effectively prevent the office door from being opened illegally and protect the safety of company property and commercial secrets. Its modern and simple design style complements the decoration style of the office building, enhancing the professionalism and quality of the overall office environment. After actual use tests, in the office building of a large enterprise, the service life of this door handle reached more than 12 years, far exceeding the service life of ordinary door handles. At the same time, the smoothness and quietness of the door handle have been highly praised by the company's employees, who believe that it will not generate noise to interfere with work during daily use, effectively improving the comfort and efficiency of the office environment.

6. Commercial buildings

In commercial buildings, such as shopping malls and exhibition halls, door handles need to face a large number of customers and high frequency of use. The durability and safety of the Stainless Steel Mortise Handle make it an ideal choice for these places. Its specially treated surface can withstand long-term touch and friction, maintaining a bright and new appearance. In terms of security, the high-precision lock cylinder and solid lock tongue of the door handle can effectively prevent theft and illegal intrusion in commercial places. A large shopping mall selected this door handle when it opened. After years of use, the failure rate of the door handle is less than 5%. At the same time, the security department of the shopping mall reported that the locking performance of the door handle effectively prevented the accidental opening of the shop door during business hours, ensuring the property safety of the merchants and improving the overall safety management level of the commercial place.

Stainless Steel Mortise Handle Maintenance:

1. Daily cleaning

Keeping the Stainless Steel Mortise Handle clean is one of the important measures to extend its service life. In daily use, the surface of the door handle should be gently wiped with a soft dry or slightly damp cloth regularly to remove fingerprints, dust and stains. For door handles with surface treatments such as PVD and CP, avoid using detergents containing abrasives or strong acids and alkalis to avoid scratching the surface coating. You can use a special stainless steel cleaner. After diluting it according to the product instructions, use a soft cloth to dip the cleaner and gently wipe the surface of the door handle, then rinse it with clean water and finally wipe it with a dry cloth. Performing such cleaning and maintenance once a week can effectively remove stubborn stains and keep the door handle as bright as new. During the cleaning process, pay attention to the wiping direction should be consistent with the brushed texture direction, so that the dirt in the texture can be better cleaned while avoiding damage to the surface treatment layer.

2. Regular lubrication

The internal mechanical parts of the door handle need to be lubricated regularly to ensure its smooth operation and durability. Every 3-6 months, use special lubricating oil or vaseline to lubricate the lock cylinder, shaft and other parts of the door handle. When lubricating, first open the door handle, drip an appropriate amount of lubricating oil into the lock cylinder hole and shaft, and then repeatedly turn the door handle and key to evenly distribute the lubricating oil on the internal parts. After that, wipe off the excess grease with a clean cloth to prevent it from being contaminated with dust. Regular lubrication can effectively reduce the friction between mechanical parts, prevent component wear caused by long-term dry friction, and extend the service life of the door handle. During the lubrication process, if it is found that the lock cylinder does not rotate smoothly or there is an abnormal sound, it should be checked in time whether there is a foreign object stuck inside the lock cylinder and clean it.

3. Moisture and corrosion prevention

Although stainless steel has good corrosion resistance, it may still cause rust in a humid environment for a long time. In humid areas or rainy seasons, moisture-proof measures should be taken. Desiccant, such as silica gel desiccant, can be placed near the door handle and replaced every 1-2 months to absorb the surrounding moisture. At the same time, regularly check the sealing between the door handle and the door frame to ensure that the door leaf can effectively block the entry of external moisture when it is closed. For door handles installed in high humidity environments such as near the sea or swimming pool, a thin layer of food-grade anti-rust oil can be applied to the surface every month to form a protective film to enhance its resistance to salt spray corrosion. When applying anti-rust oil, ensure that the oil layer evenly covers the surface of the door handle to avoid missing any part, and wait for it to dry naturally after application.

4. Avoid external force impact

During use, avoid applying excessive external force impact to the door handle to avoid damaging its internal structure. Educate users to avoid opening and closing the door with excessive force, especially children, who need to use door handles correctly under adult supervision. When carrying heavy objects or using cleaning tools, be careful not to collide with the door handle to prevent scratches on its surface or deformation of parts. If the door handle is accidentally slightly hit, check whether its appearance and function are affected in time. If there are minor scratches on the surface of the door handle, you can use a repair agent that matches the surface treatment of the door handle to repair it. Follow the product instructions to operate, which can generally effectively fade the scratches and restore the surface gloss. If the parts are loose or damaged due to collision, you should contact professional maintenance personnel in time to repair or replace them to avoid the expansion of the fault.

5. Check the lock cylinder regularly

Every 3-6 months, conduct a comprehensive inspection of the lock cylinder of the door handle. Use the key to repeatedly insert and remove the lock cylinder to check whether the lock cylinder rotates smoothly and whether there is any jamming. If you find that the key is difficult to insert and remove or the lock cylinder is not flexible, you can first try to lubricate it with a special lock cylinder lubricant. Spray the lubricant into the lock cylinder hole, and then turn the key repeatedly to evenly distribute the lubricant inside the lock cylinder. If the problem is still not solved after lubrication, it may be that foreign matter has entered the lock cylinder or the lock cylinder parts are worn. You should contact a professional locksmith for inspection and repair in time. Regular inspection of the lock cylinder can detect and solve potential problems in time, ensure that the locking performance of the door handle is always in good condition, and ensure the safety of users.